All Categories

BAOSHISHAN 200ml Hydrothermal Autoclave Reactor, 304 Stainless Steel Polytetrafluoroethylene Lined for Lab Hydrothermal Process (200ml)

Share Tweet

BAOSHISHAN 200ml Hydrothermal Autoclave Features

-

Max Temperature: 180C. Max Pressure: 3Mpa. Heating/Cooling Rate: 5 C/min. Material: 304 Stainless Steel. Chamber: PTFE.

-

ENSURE SAFETY: Made from durable, reliable seal structure, which ensures long-term stability and prevents seeping problem or leakage. The matching PTFE lining withstand high temperature and pressure, corrosion resistant, insoluble in almost all solvents, and physically inert.

-

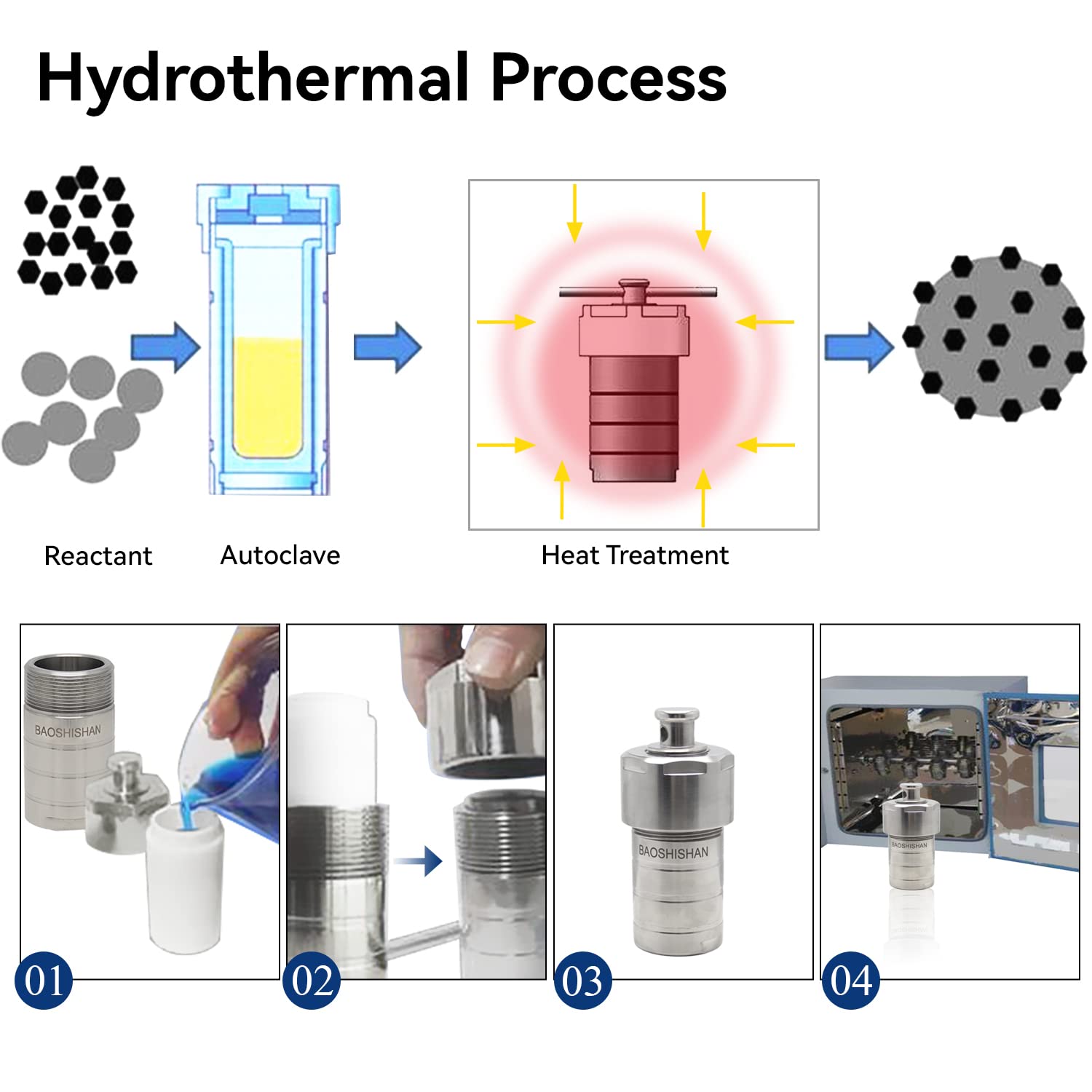

EXPERIMENTAL USE. The hydrothermal synthesis reactor is a closed vessel mainly used for hydrothermal synthesis, crystal growth or sample digestion and extraction. The autoclave has been designed to use for external heating where the reactor can be heated in the oven, furnace or self-heating.

-

VARIOUS MODELS AND LINERS. BAOSHISHAN developed and supply multiple reactor vessel including capacity 25ml, 50ml, 100ml, 200ml, 300ml and 500ml. These are also available in corresponding liners.

-

OUR GOAL: BAOSHISHAN offers high-pressure hydrothermal autoclave reactor and customized for each application and supported by highly competent and skilled staff.

About BAOSHISHAN 200ml Hydrothermal Autoclave

-How to choose the reactor? -Capacity, pressure, temperature, whether acid and alkali resistant... Capacity: First confirm the capacity of your reaction solution (if your reaction solution is 30ml, it is recommended to buy a 100ml reactor, the reactor should be added with 1/3 of the solution when it is used for the first time) Temperature and pressure: Then confirm the temperature and pressure you need (you can choose according to the applicable range of each reactor) Whether it can react with acid-base solution: PTFE liner can be used to react acid-base solution, but PPL liner cannot. Pour the reactant into the PTFE liner and ensure that the feeding is less than 50%, and for the first time must less than 30% Suggested Heater: It is recommended use a heater with programmed heating, muffle furnace is not recommended, becasue of temperature overshooting and temperature heating rate exceed the limit will lead to melting of the lining.