All Categories

BAOSHISHAN 25ml Hydrothermal Autoclave Reactor, 304 Stainless Steel Polytetrafluoroethylene Lined for Lab Hydrothermal Process (25ml)

Share Tweet

Get it between 2025-02-27 to 2025-03-06. Additional 3 business days for provincial shipping.

*Price and Stocks may change without prior notice

*Packaging of actual item may differ from photo shown

- Electrical items MAY be 110 volts.

- 7 Day Return Policy

- All products are genuine and original

- Cash On Delivery/Cash Upon Pickup Available

BAOSHISHAN 25ml Hydrothermal Autoclave Reactor, 304 Features

-

Max Temperature: 180C. Max Pressure: 6Mpa. Heating/Cooling Rate: 5 C/min. Material: 304 Stainless Steel. Chamber: PTFE.

-

ENSURE SAFETY: Made from durable, reliable seal structure, which ensures long-term stability and prevents seeping problem or leakage. The matching PTFE lining withstand high temperature and pressure, corrosion resistant, insoluble in almost all solvents, and physically inert.

-

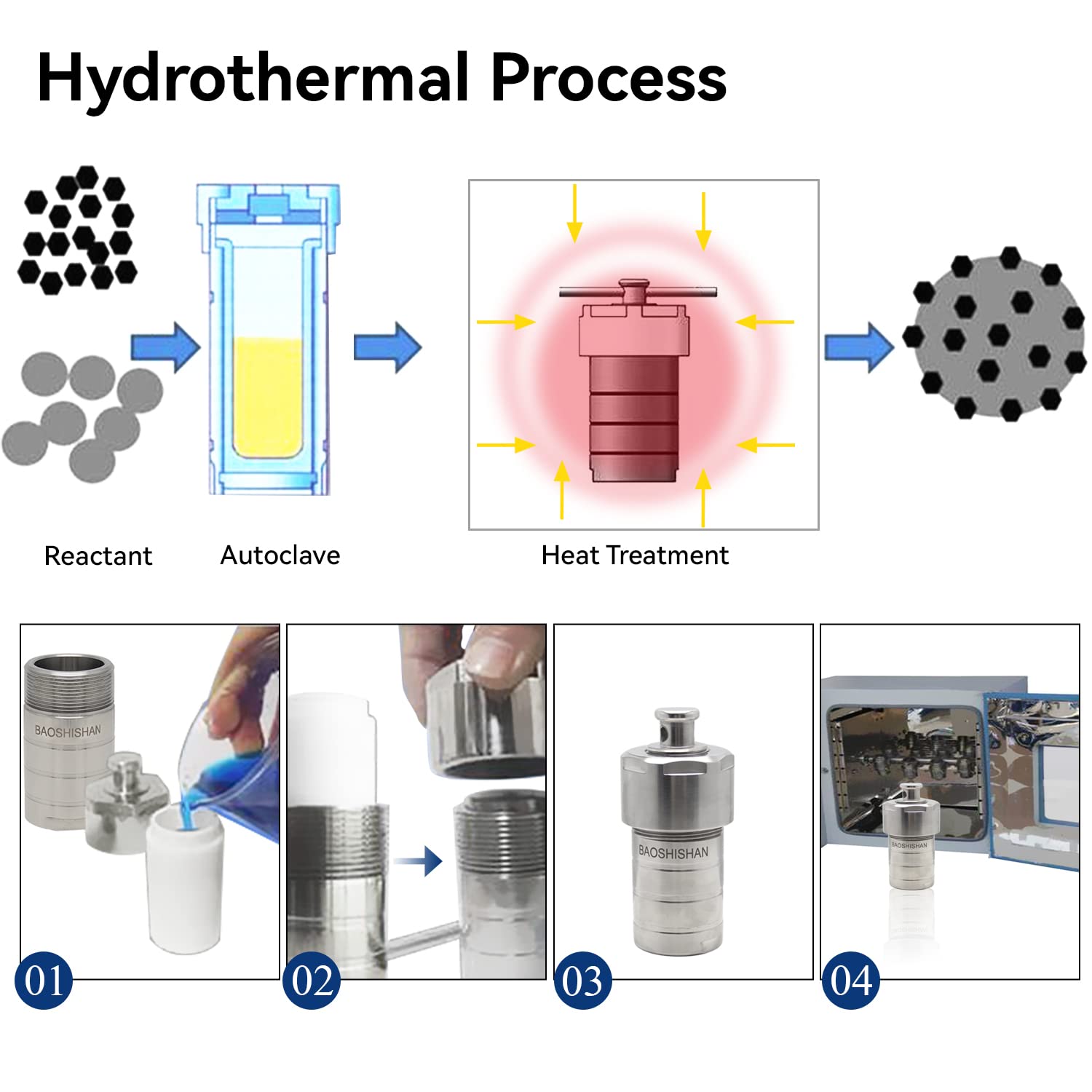

EXPERIMENTAL USE. The hydrothermal synthesis reactor is a closed vessel mainly used for hydrothermal synthesis, crystal growth or sample digestion and extraction. The autoclave has been designed to use for external heating where the reactor can be heated in the oven, furnace or self-heating.

-

VARIOUS MODELS AND LINERS. BAOSHISHAN developed and supply multiple reactor vessel including capacity 25ml, 50ml, 100ml, 200ml, 300ml and 500ml. These are also available in corresponding liners.

-

OUR GOAL: BAOSHISHAN offers high-pressure hydrothermal autoclave reactor and customized for each application and supported by highly competent and skilled staff.

About BAOSHISHAN 25ml Hydrothermal Autoclave Reactor, 304

BAOSHISHAN 100ml Teflon Lined Hydrothermal Synthesis Autoclave Reactor 220℃ 3Mpa 304 Steel High Pressure Digestion Tank PTFE Vessel Acid and Alkali Resistance Specification: Volume:25/50/100/150/200/250/300/500ml, other customized according to user needs Seal Structure: sealed by PTFE chamber Shell Material: stainless steel 304 Chamber Material: high quality PTFE Heating/ Cooling rate: 5c/min Max temperature: 220℃ Max pressure: 3Mpa Feature: 1.Insulation, high lubrication. 2.No adhesion, no poison;Anti-pollution, anti-leakage. 3.Good corrosion resistance, no harmful substances spill. 4.Pollution reducing, use safety. 5.After heating and boost, it can quickly and easily dissolve samples that are difficult to dissolve and samples containing volatile elements in the conventional conditions. 6.Shortened the analysis time but reliable data. 7.With polytetrafluoroethylene bushing, acid and alkali resistant. 8.Able to replace platinum crucible to solve sample treatment problem about the trace Element analysis on high purity alumina. How to use it - Pour the reaction into the reactor kettle, and to ensure feeding coefficient is less than 0.8. - You should put the corrosive reaction into PTFE bush, be assured kettle body from corrosion. - Hydrothermal synthesis reactor will be placed on the heater, in accordance with the provisions of the heating rate of heating to the desired reaction temperature (less than the required safety temperature). - When finishing heating and need to cool, it's also in strict accordance with the provisions of the cooling rate operation, to facilitate the safety and reactor life.