All Categories

Brush Research BC7824 FLEX-HONE®, 7/8"(22.2mm) Diameter, 240 Grit, Silicon Carbide Abrasive (Pack of 1)

Share Tweet

Get it between 2024-12-11 to 2024-12-18. Additional 3 business days for provincial shipping.

*Price and Stocks may change without prior notice

*Packaging of actual item may differ from photo shown

- Electrical items MAY be 110 volts.

- 7 Day Return Policy

- All products are genuine and original

- Cash On Delivery/Cash Upon Pickup Available

Brush Research BC7824 Features

-

[QUALITY]- Proudly Made in the USA. The FLEX-HONE is long lasting, lowering total cost of use compared to other brush options.

-

[DESIGN]- The FLEX-HONE is manufactured to be self-centering, self-aligning and self-compensating for wear for easy use.

-

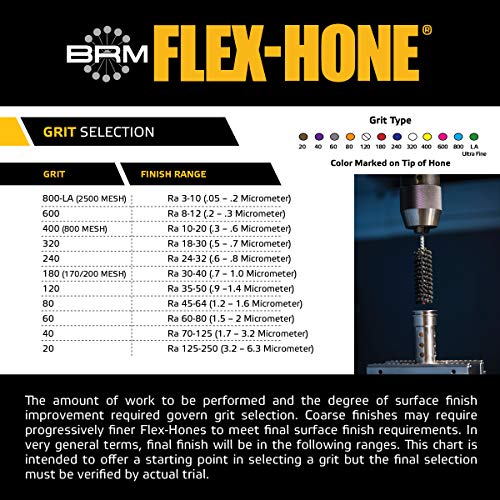

[FINISHING BENEFITS]- Offered in a wide variety of grits and abrasives to allow machinists to achieve specific finishing tolerances as well as a beautiful crosshatch finish.

-

[CROSSHOLE DEBURRING]- Ideal for finishing and deburring simultaneously in a single setup. Can be used in virtually any rotating spindle.

-

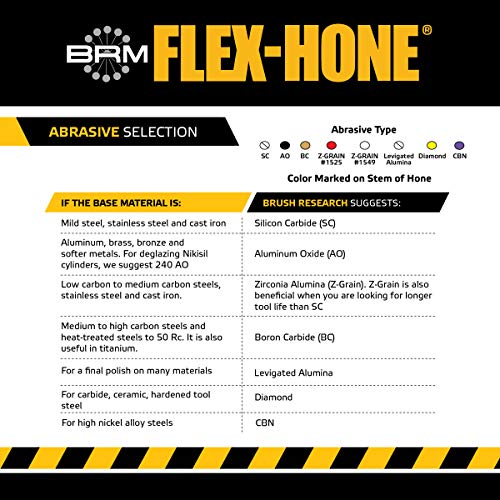

[SILICON CARBIDE ABRASIVE]- Excellent on mild steel, stainless steel, cast iron and other softer ferrous materials.

About Brush Research BC7824

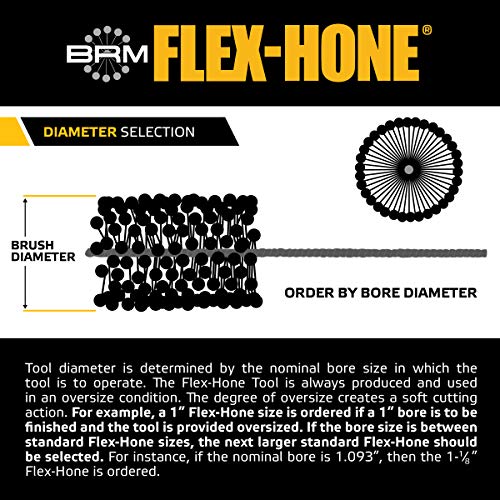

The Flex-Hone® tool was originally created by Brush Research Manufacturing to deglaze cylinder walls in automotive applications. Brush Research embraced the benefits of a plateau finish and pioneered the concept of plateau honing culminating in the introduction of the Flex-Hone tool in 1972. The Flex-Hone has gained many nicknames over the years and including ball hone, ball style hone, flexihone, dingleberry hone, bead brush, glaze breaker and glaze buster. Flexible honing with the Flex-Hone tool produces an oil holding cross hatch pattern and a true plateau finish free of cut, torn and folded metal. Any type or size of cylinder can benefit from the Flex-Hone®. These abrasive bead style brushes are produced in standard diameters from 4mm to 36 inches. Nine abrasive types are offered including silicon carbide, aluminum oxide, boron carbide and diamond allowing the tool to be tailored to finish any base material. A choice of 11 different grit selections are available for precise control of finish parameters. The elimination of peaks results in rapid ring seating, better oil control, reduced seepage in hydraulic and pneumatic applications and provides better seal performance and longer seal life. Successful applications include firearm chambers, shotgun barrels, musical instruments, combustion chambers, air compressors, pumps, valve bodies, valve guides, brake cylinders, wheel cylinders and the list goes on and on. Flex-Hone® tools are also very effective for deburring cross drilled holes, port radiusing and edge blending. Because of its unique construction, the Flex-Hone is self-centering, self-aligning, and self-compensating for wear so it does not require an elaborate set-up or special training. Deburring can be effectively automated and combined in the machining process to allow a complete cylinder finish in one operation or it can be employed as a secondary operation with equal results.