All Categories

ISEL Concentrated Air Compressor Cleaner RESCUE Oil Additive – Restore Efficiency and Performance – Effortless VARNISH and CARBON Removal in 3-Steps – Top Off Oil Sump + Run + Drain (1 Gallon)

Share Tweet

*Price and Stocks may change without prior notice

*Packaging of actual item may differ from photo shown

- Electrical items MAY be 110 volts.

- 7 Day Return Policy

- All products are genuine and original

- Cash On Delivery/Cash Upon Pickup Available

ISEL Concentrated Air Compressor Cleaner RESCUE Oil Features

-

Outstanding Carbon & Varnish Removal while maintaining equipment operation. Add directly to existing charge of lubricant. Varnish & Carbon dissolve directly into RESCUE CLEANER.

-

Cleans Critical System Components, Corrects Fouled Cooler Heating, Increased Efficiency Relieving Excess Oil Backpressure.

-

Minimize Maintenance Related Costs and Down Time, Regain Peak Equipment Efficiency and Performance.

-

Fast Acting, Non Toxic, Non Hazardous, Top-Off Compatible, High Flash Point 180F.

-

For Use In: Reciprocating, Rotary Screw, Rotary Vane, Portable Air Compressors and Industrial Blowers.

About ISEL Concentrated Air Compressor Cleaner RESCUE Oil

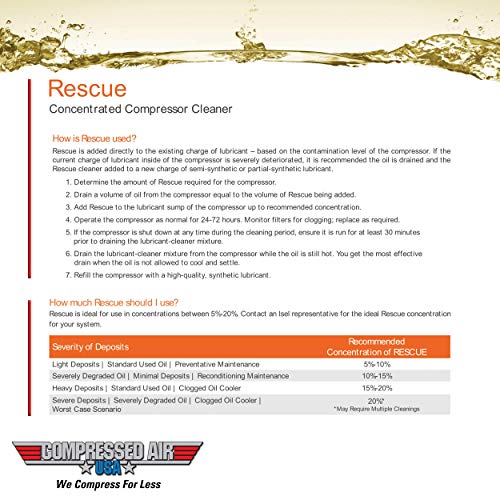

Rescue Concentrated Air Compressor Cleaner Rescue consists of premium, fast-acting concentrate cleaners. Add directly to compressor lubricant. The cleaner solubilizes contaminants into the lubricant and works to restore the compressor to peak efficiency by removing carbon, varnish and other hydrocarbon-related deposits while the equipment is operating. Drain contaminants from the system through the oil. Rescue is recommended for use at a ratio of 1 part concentrate to 10 parts lubricant. Rescue is added directly to the existing charge of lubricant – based on the contamination level of the compressor. If the current charge of lubricant inside the compressor is severely deteriorated – drain the oil and add Rescue cleaner to a new charge of semi-synthetic or partial-synthetic lubricant. DIRECTIONS FOR USE: 1. Determine amount of Rescue required for the compressor 2. Drain oil from the compressor equal to the amount of Rescue being added 3. Add Rescue to the lubricant sump of the compressor up to recommended concentration 4. Operate the compressor as normal for 24-72 Hours. Monitor filters for clogging; replace as needed 5. If the compressor shuts down at any time during the cleaning period, ensure it is run for atleast 30 minutes prior to draining the oil-cleaner mixture 6. Drain the lubricant-cleaner mixture from the compressor while oil is still hot. Oil and contaminants do not drain well when allowed to cool and settle 7. Refill the compressor with high-quality, synthetic lubricant How much Rescue to use: Light Deposits / Standard Used Oil / Preventative Maintenance = 5-10% Concentration Severely Degraded Oil / Minimal Deposits / Reconditioning Maintenance = 10-15% Concentration Heavy Deposits / Standard Used Oil / Clogged Oil Cooler = 15-20% Concentration Worst Case Scenario Severe Deposits / Severely Degraded Oil / Clogged Oil Cooler = 20% Concentration, and may require multiple cleanings