All Categories

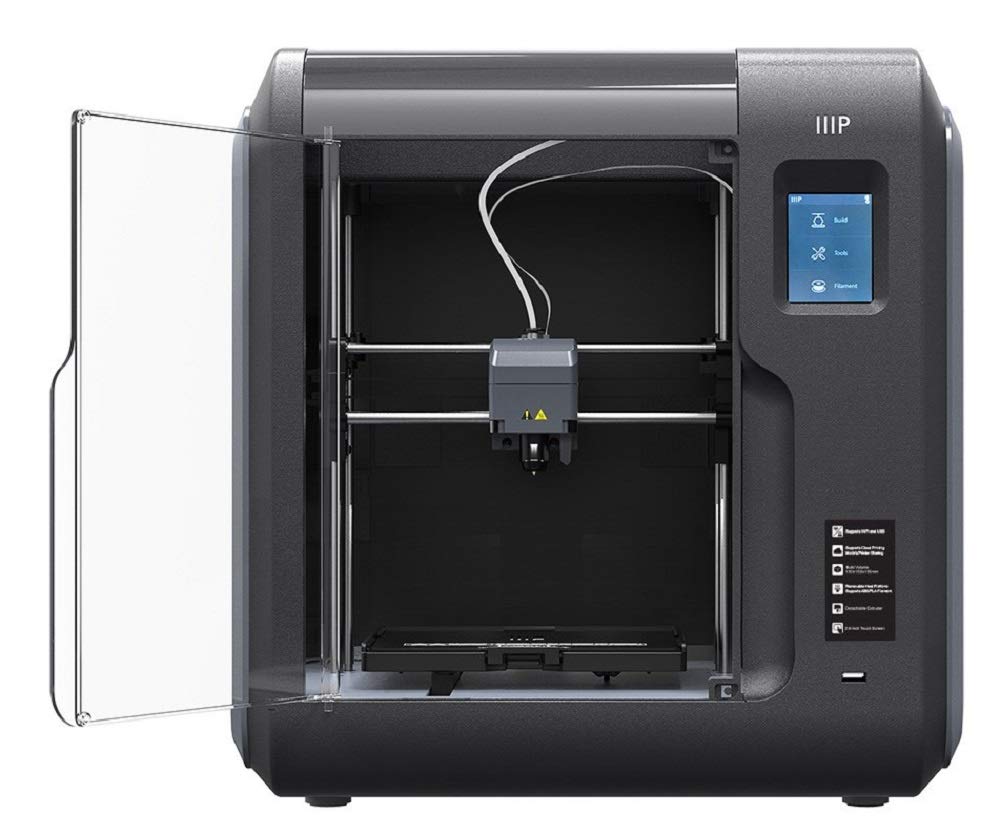

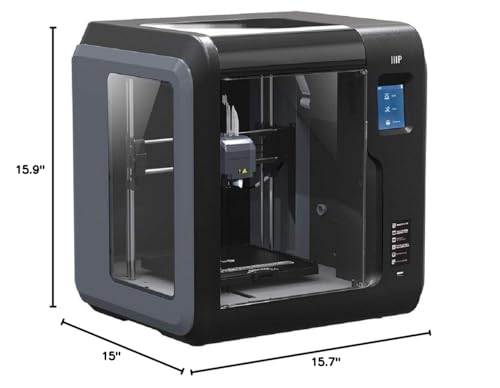

Monoprice Voxel 3D Printer - Fully Enclosed with Removable Heated Build Plate (150 x 150 x 150 mm) Touch Screen, 8GB And Wi-Fi, Black/Gray, Large

Share Tweet

Get it between 2025-03-12 to 2025-03-19. Additional 3 business days for provincial shipping.

*Price and Stocks may change without prior notice

*Packaging of actual item may differ from photo shown

- Electrical items MAY be 110 volts.

- 7 Day Return Policy

- All products are genuine and original

Monoprice Voxel 3D Printer - Fully Enclosed with Features

-

Quick change nozzle: unlike other 3D printers, which require tools and 20-40 minutes of work to replace the nozzle, The voxel has a quick change nozzle that allows you to change the nozzle in seconds, without the need for tools of any kind

-

Heated, flexible, and removable: The removable, flexible build plate makes removing a model A breeze. Simply remove and flex it to dislodge the model. You can easily replace it if it becomes damaged or can swap in a second build plate to start a new print immediately after completion of a project. Additionally, it can be heated to temperatures up to 60°c

-

Auto Leveling: the printer ships fully calibrated and ready to print out of the box. If necessary, you can easily adjust the distance between the nozzle and the bed via the touch screen interface.Operating compatibility: Windows XP/Vista/7/8/10, Mac OS X, Linux

-

Auto feeding with filament sensor: makes loading filament simple. Insert your filament into the printer’s filament loading Port, then tap ‘load filament’ on the color touchscreen menu. Additionally, a built-in sensor recognizes low filament levels and will pause prints in progress until filament is reloaded

-

Please visit Monoprice website and search for 'voxel' Or Type Part number 33820 in the search bar to visit the product page and download the latest software and manual

About Monoprice Voxel 3D Printer - Fully Enclosed With

Quick Change Nozzle: Unlike other 3D printers, which require tools and 20‑40 minutes of work to replace the nozzle, the Voxel has a quick change nozzle that allows you to change the nozzle in seconds, without the need for tools of any kind. Heated Removable Build Plate: The removable, flexible build plate makes removing a model a breeze. Simply remove and flex it to dislodge the model. You can easily replace it if it becomes damaged or can swap in a second build plate to start a new print immediately after completion of a project. Additionally, it can be heated to temperatures up to 60°C. Assisted Levelling: Assisted bed leveling makes the process of setting up the print bed as easy as a single tap to the touch screen interface. Polar Cloud Enabled: The MP Voxel comes Polar Cloud enabled straight out of the box, meaning you can control your 3D printer from anywhere with an internet connection, connect and manage multiple printers at once, queue print jobs, slice models, and even check in on how your print is doing with the built‑in web cam! The Bowden tube connector is typically a small piece that looks similar to a valve. It allows filament to feed directly into the extruder motor, which pushes filament through the heated nozzle. It is also common to refer to this part as a Bowden Coupler or Pneumatic Push Connector, as well as other names. Most connectors have a circular tab on the top of the piece, which is what keeps the PTFE tube inserted into place. Press down on this circular tab to either remove or insert the PTFE tube. Once the PTFE tube is in place, release the circular tab to secure it in place. Always press down on the circular tab before attempting to remove the PTFE tube to prevent damage to the Bowden connector. While you can use any type of filament you want, we suggest that beginners should start with PLA or PLA+ filament. This allows you to become acquainted with your new printer and get a better understanding of how it works. The table below lists the most common types of filament with use‑case suggestions and suggested temperatures. As with most mechanical objects, your 3D printer needs periodic maintenance to keep it operating at peak performance. Following are a few tips and tricks to keep in mind. Always remove filament completely when you have finished printing for the day. Allowing the filament to cool in the nozzle can cause clogging and further complications. Always double‑check the level of your print bed. Printers with Auto‑Leveling may need the offset adjusted. This will be a unique value for every printer. The space between the nozzle and the print bed should be 0.1mm, which is the thickness of a sheet of standard printer paper. Many people want to create objects for use with food or drink with their 3D printers, such as decorative plates, molds, cups, or cookie cutters. While this is indeed possible, there are several things to keep in mind. Always ensure that the filament you intend to use is food safe. This should be indicated on the product page or on the packaging. Some brands have specific types of filament that are FDA approved. FFF printing is the process of melting and extruding thermoplastics into thin layers to build a model. Printing at the lowest layer height may help prevent ridges. Truly food safe objects should have a perfectly smooth surface. Most standard thermoplastics will react to the high temperatures used with standard dish washing. It is best to use lukewarm water and an antibacterial soap. This reduces the risk of damaging the print and removes any surface bacteria. Brass nozzles are a standard part for many 3D printers. However, these may contain trace amounts of lead. Using a stainless steel to print objects for use with food or drink will eliminate any risk of lead contamination. A more in-depth explanation of 3D printer filaments. https://youtu.be/tFM3Qv3I2g0 https://youtu.be/WD_0FlTf3_I https://monopricesupport.kayako.com/article/325-commonly-used-terms https://monopricesupport.kayako.com/category/2-3d-printing-videos https://www.monoprice.com/help?pn=contact Quality at a Fair Price Monoprice's rugged design and rigid quality control standards deliver high quality products at fair prices. Hassle Free Packaging Monoprice exists to bring simplicity, fairness, and confidence to technology choices. This product features recyclable packaging that is simple to open, cost effective, with minimal waste, and fully protective as it travels to you. Service and Support You're never on your own with Monoprice products! We have a full team of friendly and knowledgeable technicians available to answer your questions, both before and after the sale. Contact our technical support team for questions about our products, troubleshooting, or even suggestions for products to fit your particular needs. Not to be outdone, our friendly and helpful customer service team is here to make your ordering, delivery, and any possible returns a quick and painless operation, from s