All Categories

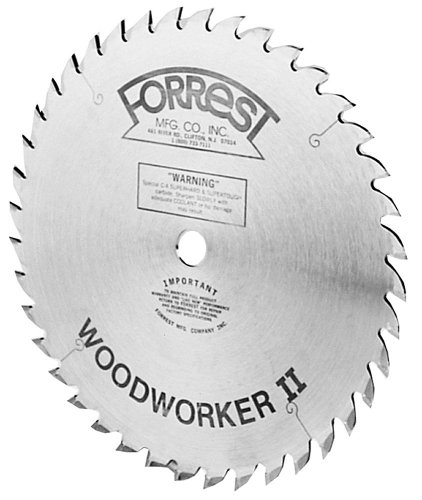

Forrest WW07Q307100 Woodworker II 7-1/4-Inch 30 Tooth 5/8-Inch Arbor 3/32-Inch Kerf Circular Saw Blade

Share Tweet

*Price and Stocks may change without prior notice

*Packaging of actual item may differ from photo shown

- Electrical items MAY be 110 volts.

- 7 Day Return Policy

- All products are genuine and original

- Cash On Delivery/Cash Upon Pickup Available

Forrest WW07Q307100 Woodworker II 7-1/4-Inch 30 Features

-

Forrest Saw Blades dampener helps kill saw scream-whistle from a vibrating blade surface.

-

Dampen out motor and belt vibrations from being transmitted up to the rim of the teeth.

-

Greatly reduce cutting noise.

-

Hold blade rigid and true for better cuts on your machine.

-

Are hardened and precision ground flat within .001" to keep your blade true.

About Forrest WW07Q307100 Woodworker II 7-1/4-Inch 30

From the Manufacturer Forrest's blades offer a superior cut that leaves a rip-cut saw edge that is as smooth as if it had been sanded, and a cross-cut edge that is almost mark-free. The blades run very quietly, and backside tearout in plywood is negligible. Each blade is virtually hand-made. The plate is hand-tensioned (up to 15 minutes per blade), superior C-4 carbide teeth are hand-brazed to the plate, and the blade is straightened and restraightened multiple times throughout the process. Think of a Forrest blade as a tool in your shop, not an accessory. Forrest stands behind it's blades by offering a sharpening service that bring blades back to the exact tolerances offered in a new blade. And this same exacting service is available for other manufacturer's blades as well, so they should come back better than new. Recommended for: thin, low pressure, two-sided laminates, plywood & fine cross cutting on all woods. Eliminates need for a small scoring saw blade on table saw work. The 40° points slice through thin bottom layers with no tears or chips. Reduced yearly sharpening costs - less machine downtime.