All Categories

TEKTON 17 mm Angle Head Open End Wrench | WAE84217 | Made in USA

Share Tweet

Get it between 2025-01-03 to 2025-01-10. Additional 3 business days for provincial shipping.

*Price and Stocks may change without prior notice

*Packaging of actual item may differ from photo shown

- Electrical items MAY be 110 volts.

- 7 Day Return Policy

- All products are genuine and original

- Cash On Delivery/Cash Upon Pickup Available

TEKTON 17 mm Angle Head Open End Wrench | WAE84217 Features

-

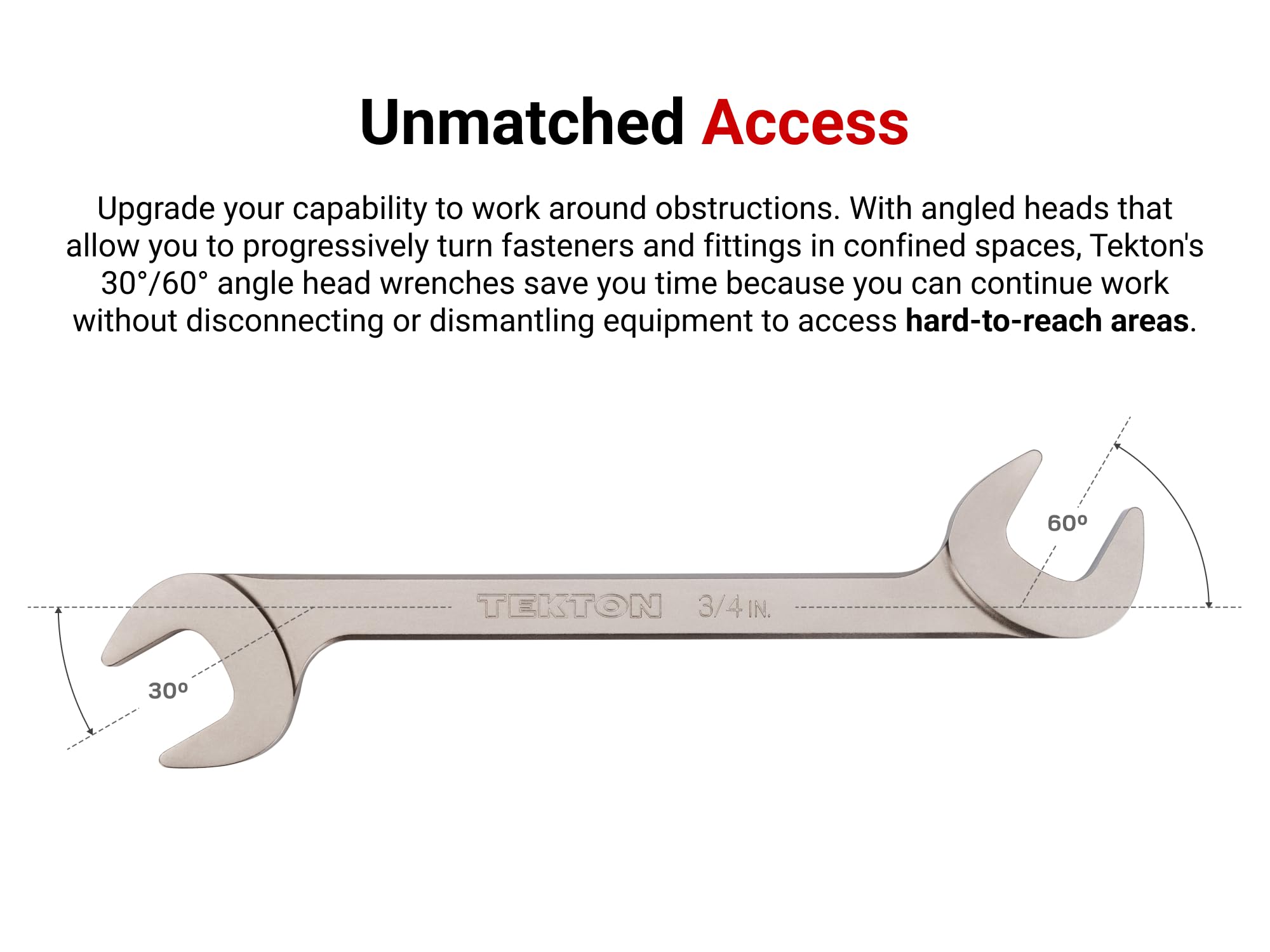

Best Combination of Angles – We paired 30 and 60 degree angled heads to achieve greater coverage with fewer blind spots in limited access situations

-

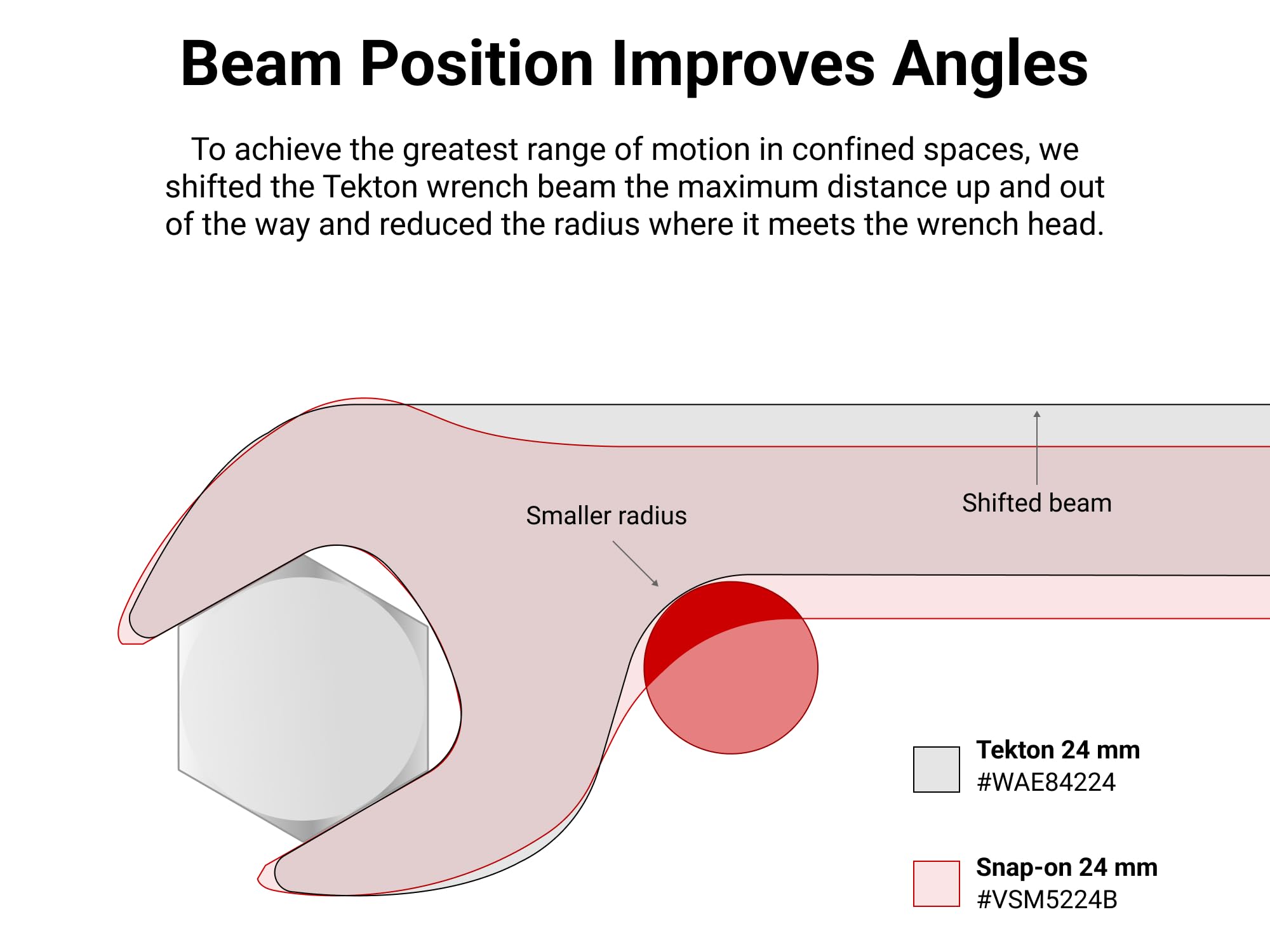

Beam Position Improves Performance – To achieve the greatest range of motion in confined spaces, we shifted the wrench beam the maximum distance up and out of the way and reduced the radius where it meets the wrench head

-

Clear Size Markings – The wrench sizes are laser engraved onto both sides of each angle wrench with a large, permanent marking that's easy to read

-

Chamfered Handle – Except for the smallest sizes, the edges of the wrench beam are chamfered to provide a smooth, comfortable grip for your hands

-

Satin Finish – Our angle wrenches are made from 4140 chromium-molybdenum steel that's hardened to 50–53 HRC and abrasive-blasted for a finely textured finish

-

Michigan Manufacturing – Machining, engraving, vibration polishing, abrasive-blasting, and plating take place at our Grand Rapids, Michigan manufacturing facility

About TEKTON 17 Mm Angle Head Open End Wrench | WAE84217

Tekton Angle Head Open End Wrenches allow you to progressively turn fasteners and fittings in confined spaces, saving you time because you can continue to work without disconnecting or dismantling equipment to access hard-to-reach areas. The 30 and 60 degree angled heads provide greater coverage with fewer blind spots in limited access situations, and the beam is shifted up and out of the way to achieve the greatest range of motion in confined spaces. The shape of the head is also optimized for access and strength while also preventing jaw spread. We make our angle wrenches from 4140 chromium-molybdenum steel and harden them to 50–53 HRC. The wrenches are abrasive-blasted to create a finely textured satin finish and then plated with corrosion-resistant nickel. The wrenches have laser-engraved size markings and (with the exception of the smallest wrench sizes) chamfered handles. Our angle wrenches are manufactured entirely in the USA with USA-made materials. Machining, engraving, vibration polishing, abrasive-blasting, and plating take place at our Grand Rapids, Michigan manufacturing facility.