All Categories

CNCTOPBAOS Nema24 3N.m Closed Loop Stepper Motor 88mm 5A,2HSS60 Hybrid Motor Driver 24-50V DC,60x60x88mm 3NM Closed-Loop Servo Motor CNC Controller Kit for CNC Router Engrvaving Milling Machine

Share Tweet

Get it between 2024-12-18 to 2024-12-25. Additional 3 business days for provincial shipping.

*Price and Stocks may change without prior notice

*Packaging of actual item may differ from photo shown

- Electrical items MAY be 110 volts.

- 7 Day Return Policy

- All products are genuine and original

- Cash On Delivery/Cash Upon Pickup Available

CNCTOPBAOS Nema24 3N.m Closed Loop Stepper Motor Features

-

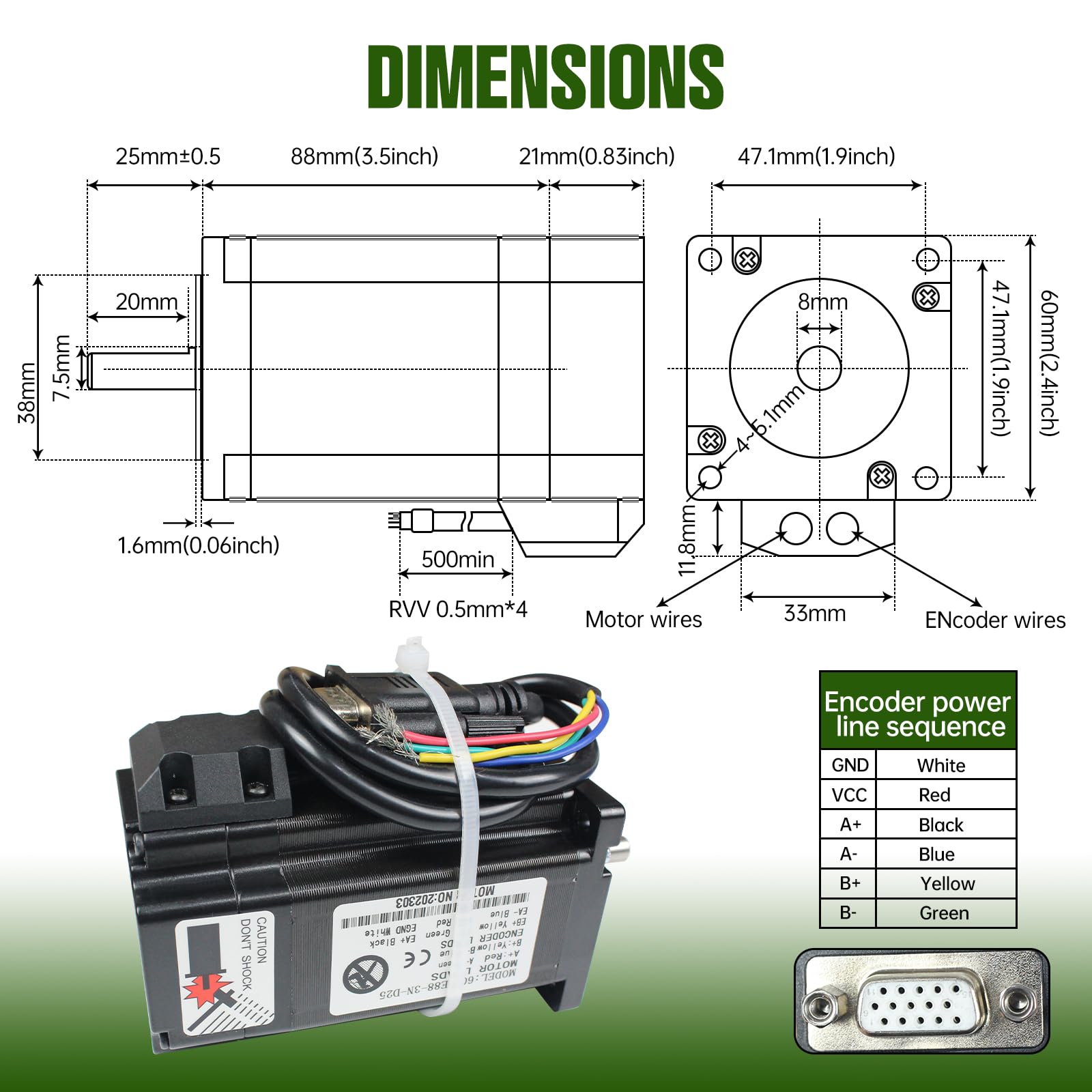

♞【Motor specifications】Holding Torque:3N.m; Current:5A; Phase:2; Size:60x60x88mm; Step Angle(degrees):1.8 degree; Motor Lead Wire: 4-wire; Encoder lines:1000

-

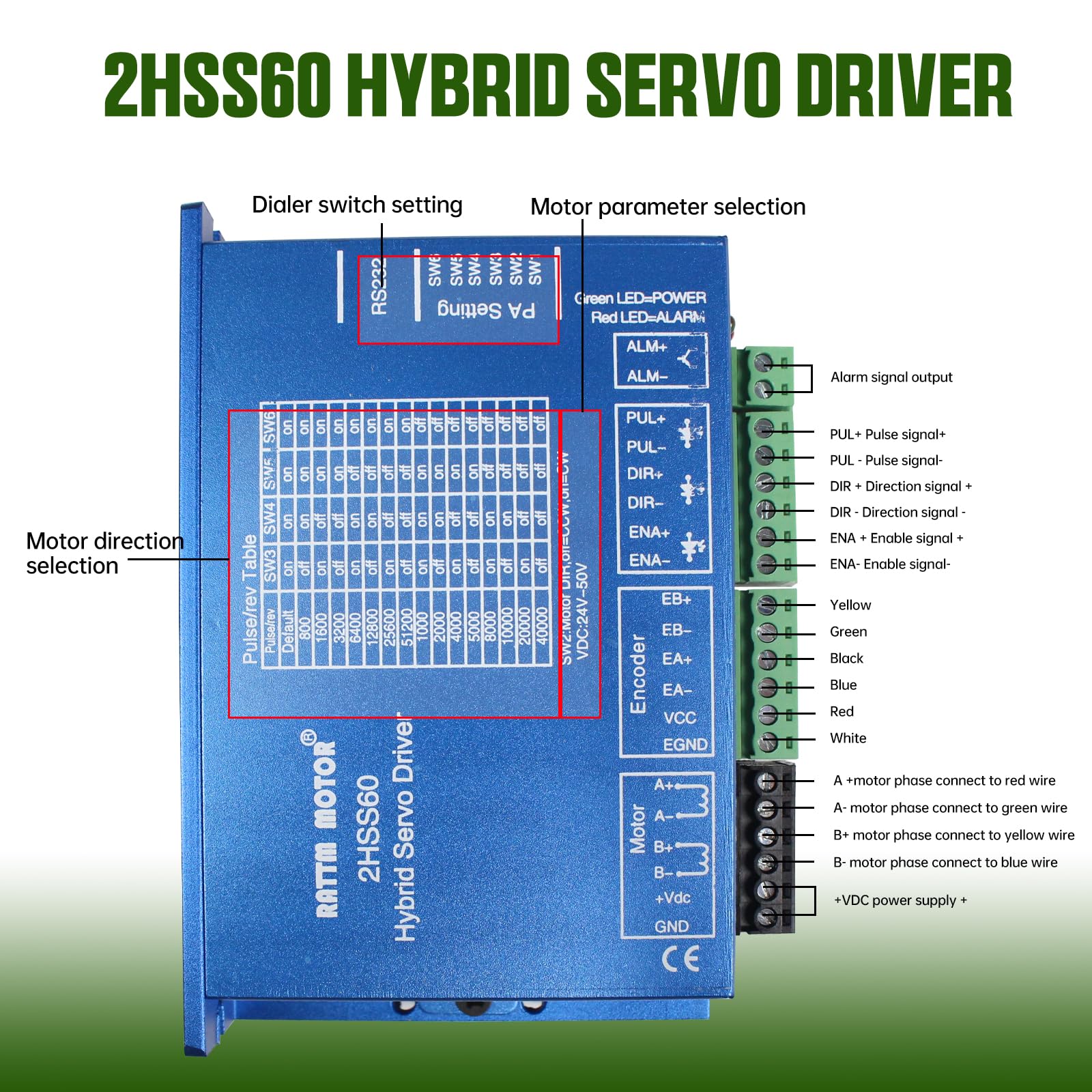

♞【2HSS60 Driver】2-Phase Hybrid Stepper Servo Driver; Frequency:0-200KHz; Insulation resistance:>=500MΩ; Voltage: DC 24-50V input;

-

♞【Advantages】Stepper motor closed loop system,never lose step; The stepper motor control has a new generation of 32-bit DSP. The vector control technology can ensure the accuracy of the motor; Improve motor output torque and working speed; Automatic current adjustment based on load; Pulses response frequency can reach 200KHZ; 16 kinds microsteps choice,highest 51200microsteps/rev.

-

♞【More Functions】It supports over-current protection, over-voltage protection, position outside the tolerance protection.The build-in place in position and alarm output signal can help the upper monitor to monitor and control,the function of position ultra difference alarm can ensure the machine work safely.

-

♞【Widely used】Closed loop stepper system can be applied to all kinds small automatic equipment and instrument. Such as engraving machine, special industrial sewing machine, stripping machine, marking machine, cutting machine, graph plotter, cnc machine, automatic assembly equipment and so on.This motor driver kit fits all types of machine load conditions (including pulley and low stiffness pulley) without adjusting the gain parameters.

About CNCTOPBAOS Nema24 3N.m Closed Loop Stepper Motor

Package include: 1 x 24HSE3N-D25 Nema24 3N.m Closed Loop Servo motor ( 88mm Length, 5A) 1 x HSS60 Servo Driver 1 x 2M Extension Wire English manual will send to your amazon email,if you don't receive the user manual,please contact us by amazon message,thanks! Features: Type:Hybrid Phase:2 Current / Phase:5A Step Angle(degrees):1.8 Holding Torque:3N.m Size:60x60x88mm Lead wire:4pcs Insulation class:B Insulation resistance:100MOhm(500V) Frequency:0~200KHz 2. HSS60 2-Phase Hybrid Stepper Servo Driver 2.2) Features 2.2.1 Stepper motor closed loop system, never lose step. 2.2.2 Improve motor output torque and working speed. 2.2.3 Automatic current adjustment based on load, lower temperature rising. 2.2.4 Suitable for all mechanical load conditions (include low rigidity belt pulley and wheel), no need to adjust gain parameter. 2.2.5 Motor work smoothly and low vibration, high dynamic performance at acceleration and deceleration. 2.2.6 No vibration from high speed to zero speed. 2.2.7 Drive nema 24 series 3N.m closed loop stepper motor. 2.3 ) Electrical Parameter Voltage rangeDC24~50V Peak currentPeak 6.0A (current change according to load) Logic input current7~20mA Frequency0~200KHz Suitable motor60HSE3N Encoder lines1000 Insulation resistance>=500MΩ 2.4) Applications Closed loop stepper system can be applied to all kinds small automatic equipment and instrument. Such as engraving machine, special industrial sewing machine, stripping machine, marking machine, cutting machine, laser phototypesetting, graph plotter, cnc machine, automatic assembly equipment and so on.