All Categories

Microcrystalline Cellulose Powder 102 | Pharmaceutical Grade Binding Agent (Packaging May Vary)

Share Tweet

Get it between 2025-02-26 to 2025-03-05. Additional 3 business days for provincial shipping.

*Price and Stocks may change without prior notice

*Packaging of actual item may differ from photo shown

- Electrical items MAY be 110 volts.

- 7 Day Return Policy

- All products are genuine and original

- Cash On Delivery/Cash Upon Pickup Available

Microcrystalline Cellulose Powder 102 Features

-

SUPERIOR TABLET CONSISTENCY: Larger particle size distribution improves formulation flow for uniform tablet and capsule filling

-

FAVORABLE TABLET FORMATION PROPERTIES: Used as binder for harder tablets in dry blended and roller compacted formulations; Ideal for wet-granulation due to water insolubility

-

HEALTHY INGREDIENT: This tasteless, non-caloric excipient is a natural source of dietary fiber; inert and will not react with other ingredients

-

SAFE AND CERTIFIED TO MEET YOUR DIETARY NEEDS: One of the most common and effective fillers thst is GRAS, or generally recognized as safe; LFA's MCC is vegetarian, kosher, and halal certified

-

MADE IN THE USA: LFA excipients are manufactured in Fort Worth, Texas to cGMP standards. Our facilities are ISO 9001:2015 & ISO 22000:2018 certified. Each batch is third party tested to meet pharmaceutical tablet manufacturing food safety requirements.

About Microcrystalline Cellulose Powder 102

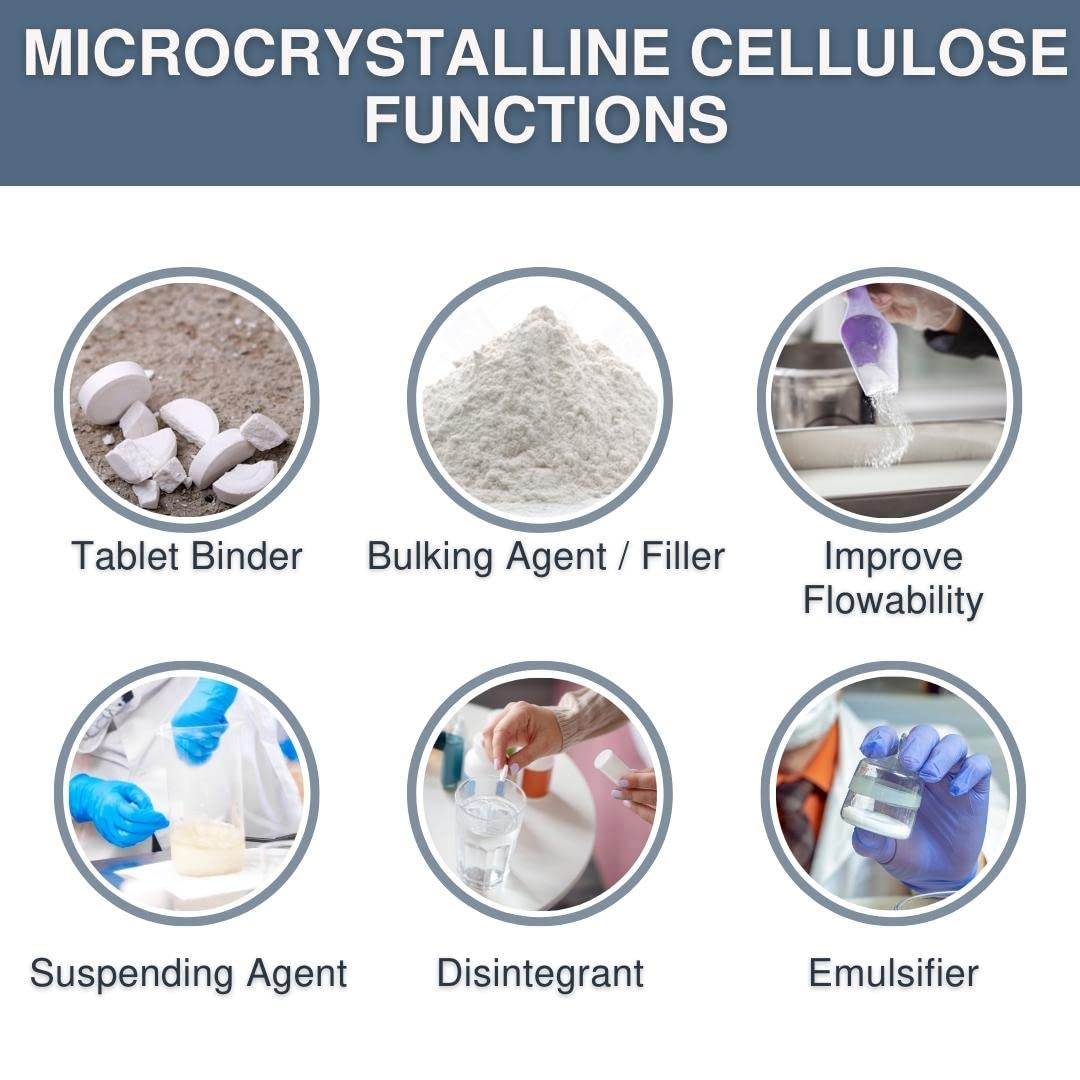

What exactly is the ideal excipient? The one which helps make ingestion easier for customers and manufacturing simpler for producers. Not just an excipient which is permissible to use, but one that stretches beyond standard functionality. Microcrystalline cellulose may be the exact binding agent you are searching for. It won't gel like methyl-cellulose and if compared to other binding agents it appears to provide the optimal degree of brittleness whilst staying lubricant sensitive. SpecificationsCAS number: 9004-34-6Molecular formula: (C6H10O5)nAppearance: Fine white powderPhysical state: SolidStorage: Store at room temperatureMelting point: 260–270 °C; 500–518 °F;Density: 1.5 g/cm3Bulk Density: 0.4g/cm3Solubility in water: None Microcrystalline Cellulose, generally named MCC, is produced in a controlled environment. The end result is a pure, white powder without any taste or smell, able to add form and hardness to your tablets. MCC maintains the necessary advantages of a diluent. It is effective as a bulking agent in your tablet or capsule, giving the desirable weight for your customers. Microcrystalline cellulose has minimal bulk density, increasing flow characteristics. Easy flow helps to ensure that each ingredient is consistently spread throughout a mixture. If the mix is consistent, each tablet will have the same quantity of each ingredient at the end of production, creating a quality product. Microcrystalline Cellulose really does its job, and also it does it well. It works well with many other popular excipients and is a integral part of many manufacturers formulas. Binders undoubtedly are a crucial element in the tableting process simply because they ensure “hardness” in a tablet.