All Categories

McGard 24215 Chrome Cone Seat Wheel Locks (M14 X 1.5 Thread Size) - Set of 4

Share Tweet

Get it between 2024-12-18 to 2024-12-25. Additional 3 business days for provincial shipping.

*Price and Stocks may change without prior notice

*Packaging of actual item may differ from photo shown

- Electrical items MAY be 110 volts.

- 7 Day Return Policy

- All products are genuine and original

- Cash On Delivery/Cash Upon Pickup Available

McGard 24215 Chrome Cone Seat Wheel Locks Features

-

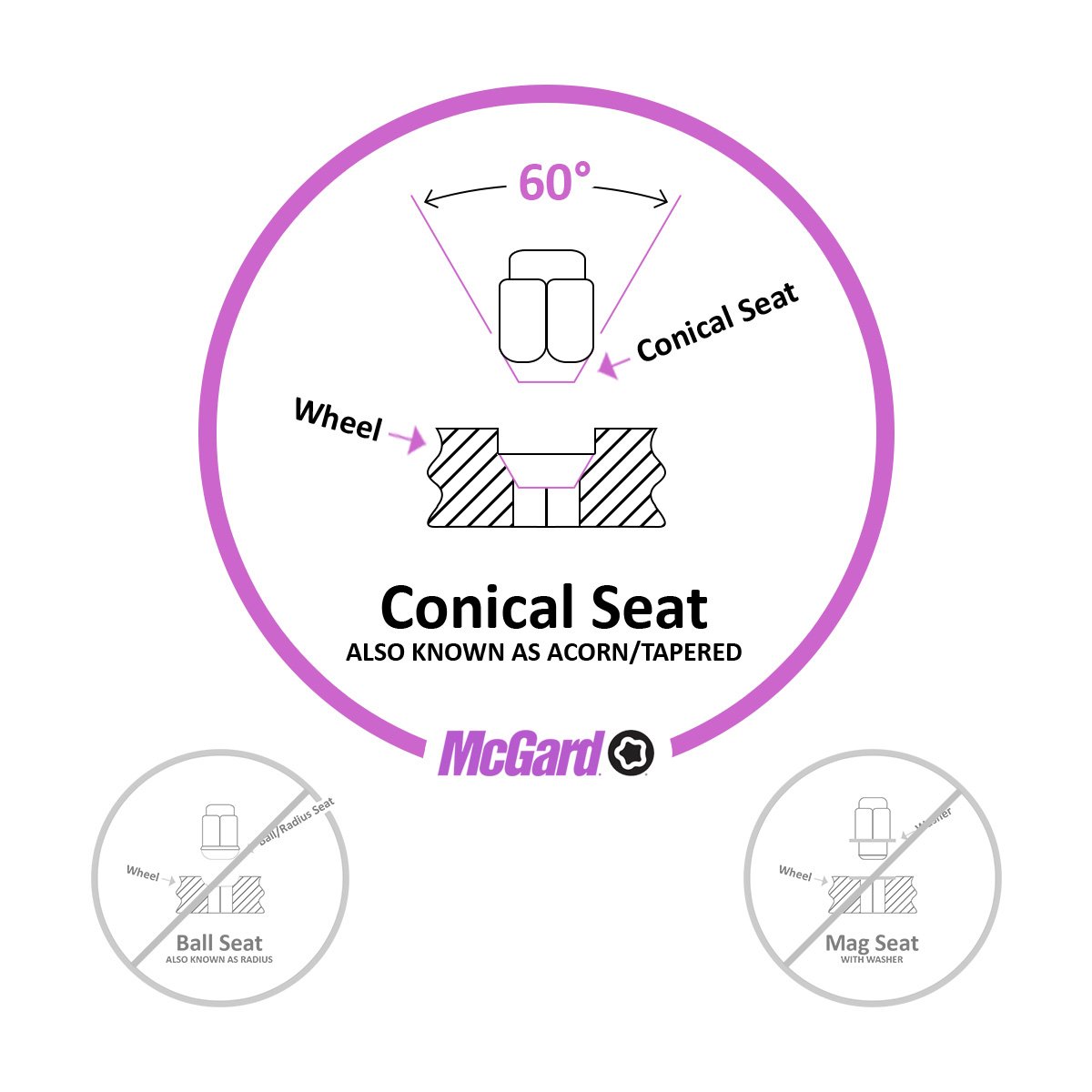

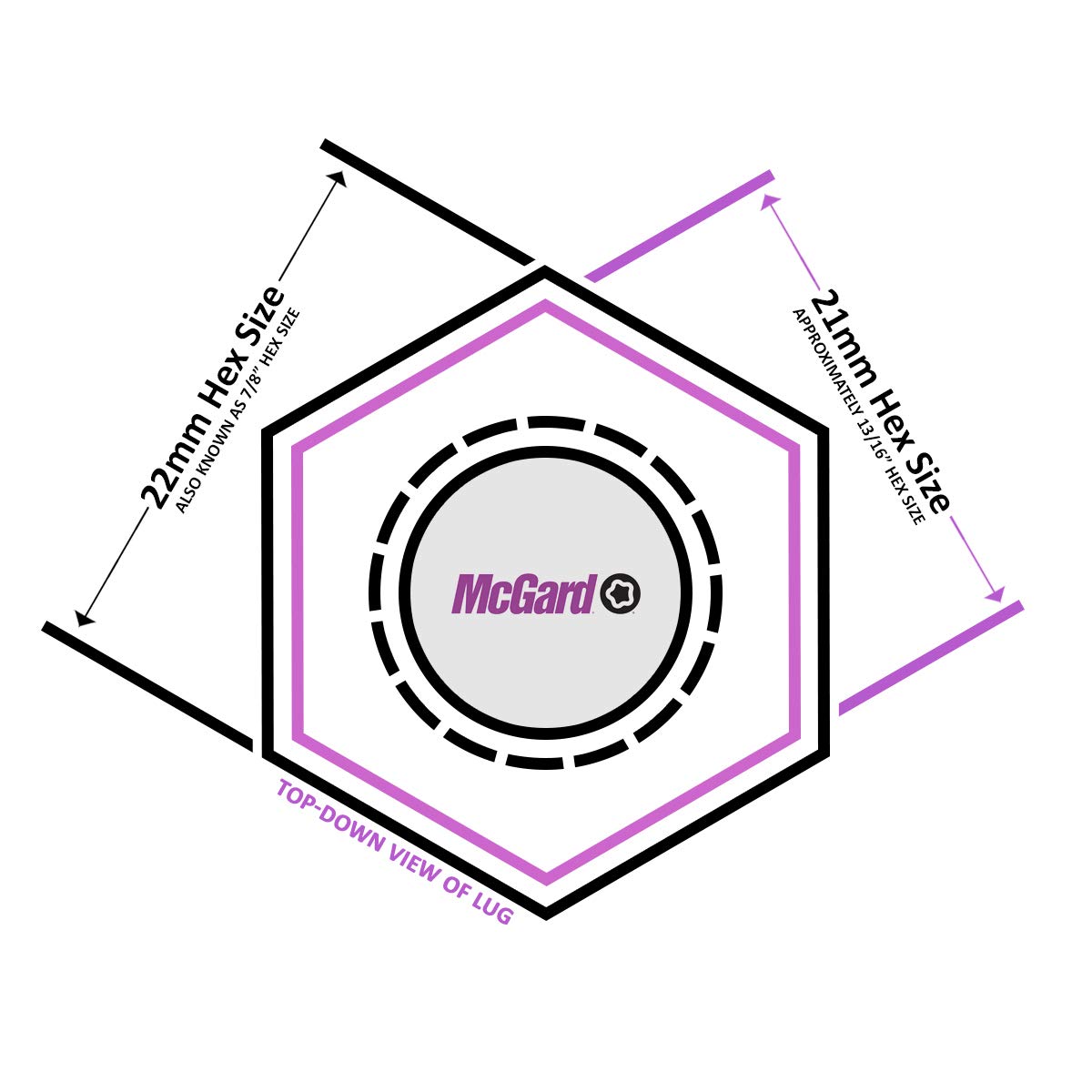

Seat Style Cone Seat Nut; Thread Size M14 x 1.5; Overall Length 1.639; Hex Size 21mm & 22mm Dual Hex; Includes 4 Locks & 1 Key.Note: Measure your door's backset, cross bore and thickness to ensure you find the right fit.Note: Measure your door's backset, cross bore and thickness to ensure you find the right fit.

-

For use with steel or aluminum wheels with lug nuts that utilize a 60 degree tapered cone seat at the bottom. Kit includes Wheel locks, unique key tool and ID card

-

McGard’s plating process includes several layers of nickel and one layer of microporous chrome producing a superior finish while protecting against rust. Every lock is through-hardened and tempered. Manufactured in the USA to meet or exceed OEM standards

-

Please note that wheel lock sets are application-specific products. You must confirm proper fitment for your vehicle by using the Amazon part finder or consulting our website. Please review important fitment notes provided. Also note the type of seating your wheel locks require they can be either radius, flat or cone seat this has to be done visually by the customer to insure a proper fit before purchase and install along with correct shank length and thread size that matches your current lug nuts

-

Due to the unique key patterns, the pattern shown in images will differ from the pattern on the locks you receive. If ordering multiple lock sets, the keys will not match. Computer generated key designs allow for an infinite number of key patterns, keys are not interchangeable with other McGard wheel locks. McGard keys will not match OEM locks installed by the factory or dealership.

About McGard 24215 Chrome Cone Seat Wheel Locks

Product Description Protecting the world’s finest wheels and tires from theft since 1964. McGard manufactures wheel locks in the USA to meet or exceed OEM standards for safety and durability. Presently, McGard is an Original Equipment wheel lock supplier to over 30 car lines around the world. These easy-to-use, one-piece wheel locks function like regular lug nuts, but require a special key tool for installation and removal. The steel collar on the user friendly key guides the key into the lock pattern. The collar holds the key in alignment for easy installation and removal. The computer generated key designs allow for an infinite number of key patterns. The extra narrow pattern groove on the lock resists the intrusion of removal tools into the pattern. Every McGard wheel lock is fully machined from restricted chemistry steel made specifically for McGard and through-hardened for its unsurpassed level of security. McGard’s plating process includes three layers of nickel and one layer of microporous chrome producing a superior finish while protecting against rust. This product may contain globally sourced materials/components. Amazon.com McGard’s easy to use, one-piece wheel lock functions like a regular lug nut or bolt, but requires a special key tool for installation and removal. Its design allows for an unlimited number of different computer generated lock and key patterns. This unique wheel lock system is continually being refined and improved upon. McGard Locks are made in the United States to meet or exceed O.E.M. standards for safety and durability. Presently, McGard is an Original Equipment wheel lock supplier to over 30 car lines around the world. Compare our features and you’ll see why McGard is the best wheel & tire protection available. 1. 8 Different Key Hex Sizes McGard is the only manufacturer to offer 8 different key hex sizes to match the vehicle’s original equipment lug wrench. Your customer will appreciate this important feature when they have to change a flat tire along the roadside. 2. User Friendly Keys The Wheel Lock's steel collar guides the key into the lock pattern. Simply place the key over the lock and turn until the patterns engage. The collar holds the key in alignment for easy installation and removal. 3. Extra Narrow Groove Patterns The computer generated key designs allow for an unlimited number of key patterns. The narrow groove resists the intrusion of lock removal tools into the pattern. 4. Triple-Nickel Chrome Plating The best in the industry. Our process includes three layers of nickel and one layer of microporous chrome. The first layer of nickel is for corrosion resistance; the second layer of nickel is for luster and the third nickel layer interacts with the microporous chrome layer to disperse nature’s corrosive action (rust). 5. Through-Hardened Steel McGard uses only restricted chemistry steel, made in the United States, specifically for McGard. These special standards insure the structural integrity of each and every fully machined McGard wheel lock. Every lock is through-hardened and tempered, reaching the depth of hardness needed for its unsurpassed level of security (unlike case hardening which is only a surface treatment). 6. Precision Threads Core integrity and precision machining provide the highest strength in the industry. All McGard locks and lug nuts meet or exceed the highest OEM proof load standards, 135,000 to 160,000 PSI. 7. Precise Bearing Surface McGard’s standard for concentricity of the bearing surface to the pitch diameter is 30% more precise than OEM standards. This insures even distribution of the clamp load and uniform seating of the lock to the wheel.

(1)

(1)