All Categories

Lesnow Solder Wicks braid,Solder Sucker,10ft Length 5 Pieces No-Clean Desoldering Braided Wicks. Solder Removal Tool,Desoldering Wick Used to Remove the Solder and Disassemble Electrical Components

Share Tweet

Get it between 2025-03-26 to 2025-04-02. Additional 3 business days for provincial shipping.

*Price and Stocks may change without prior notice

*Packaging of actual item may differ from photo shown

- Electrical items MAY be 110 volts.

- 7 Day Return Policy

- All products are genuine and original

- Cash On Delivery/Cash Upon Pickup Available

Lesnow Solder Wicks braid,Solder Sucker,10ft Features

-

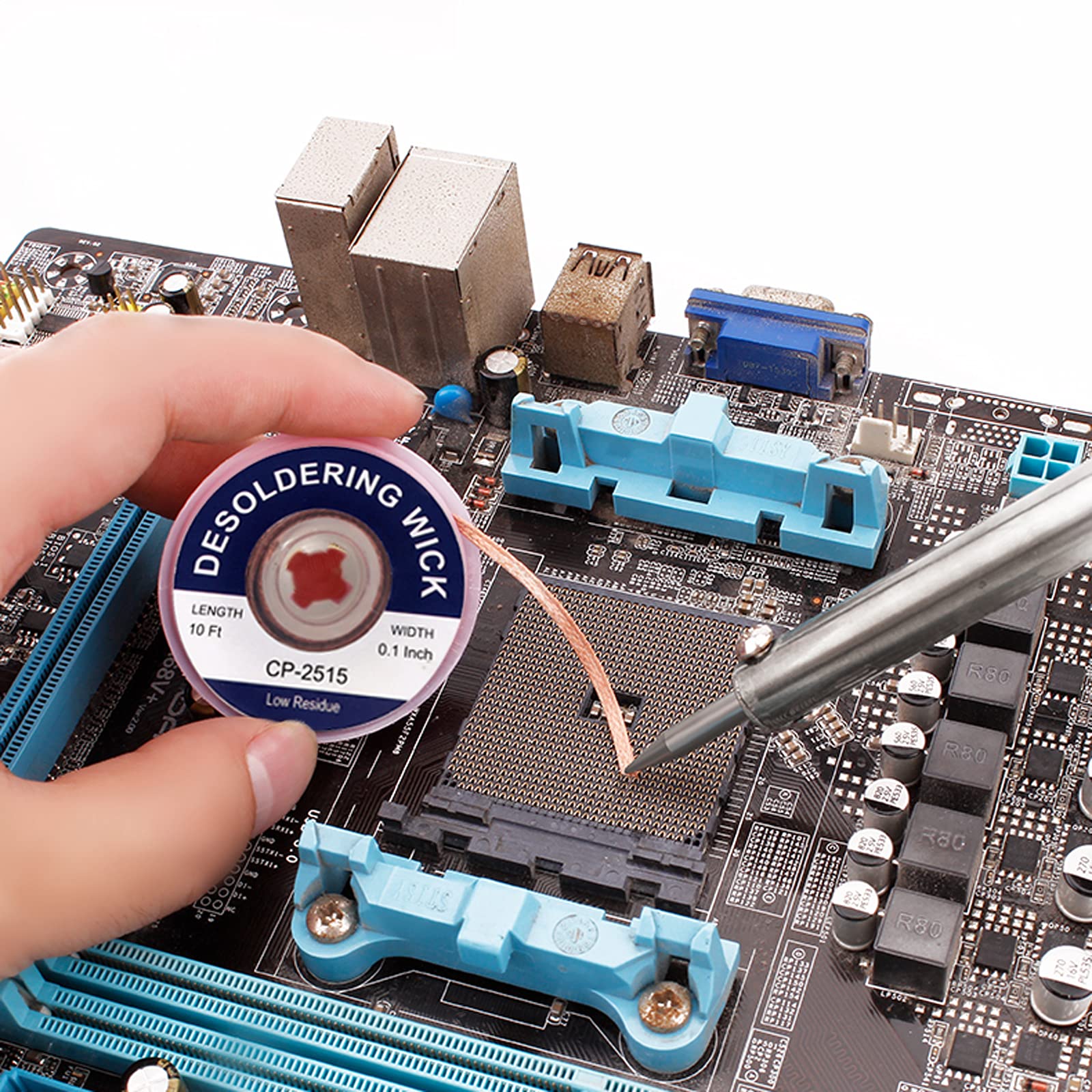

1.The solder wicks can be used to correct mistakes with small boards on PCBs, remove relays and other components from printed circuit boards, re-solder mechanical keyboard switches, unsoldering old wire from devices, desoldering computer parts such as a motherboard,clean alloy on smd components and more

-

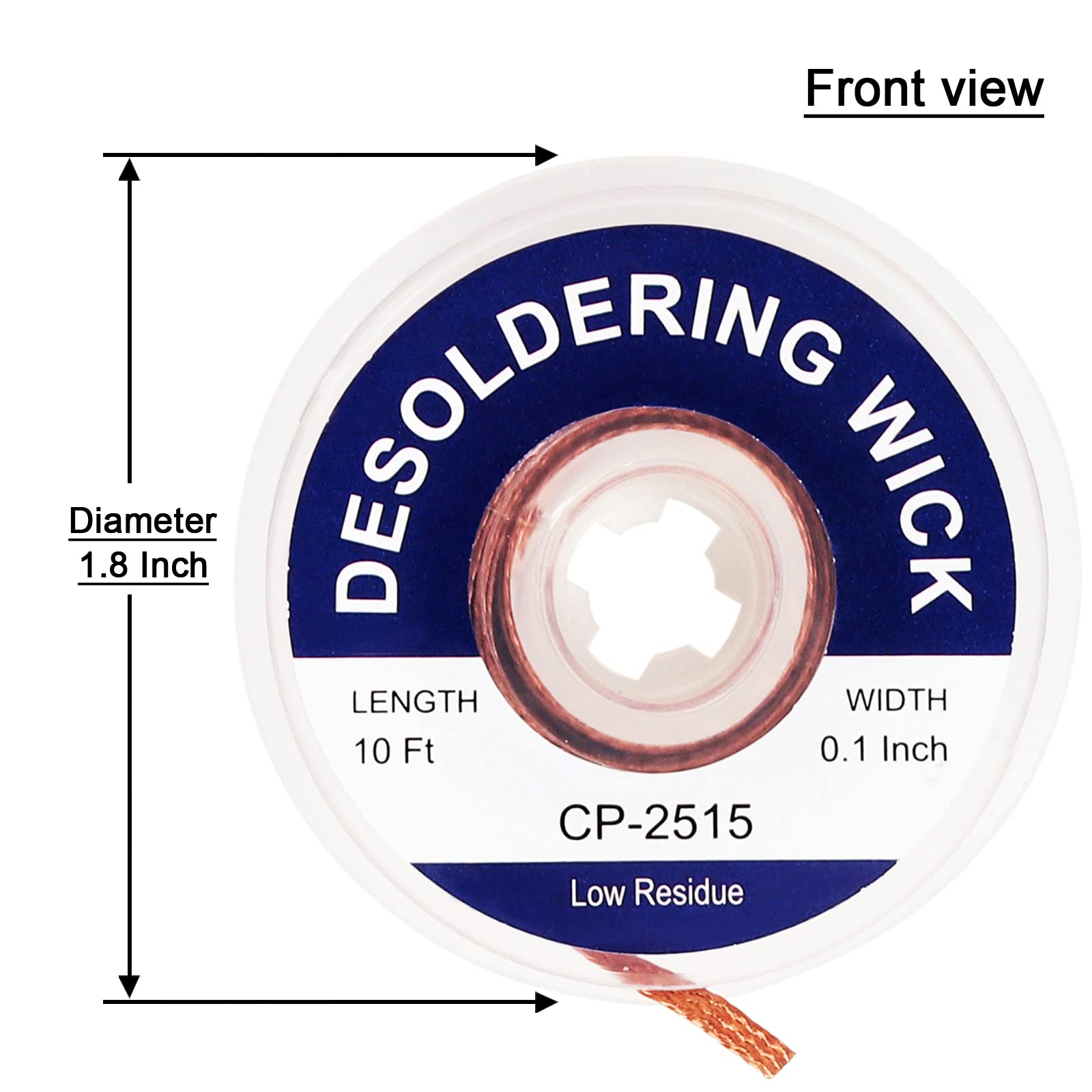

2.1 pieces of no-clean solder wicks, each wick is about 10ft long and 0.1 inch in width, enough quantity and length for your daily needs

-

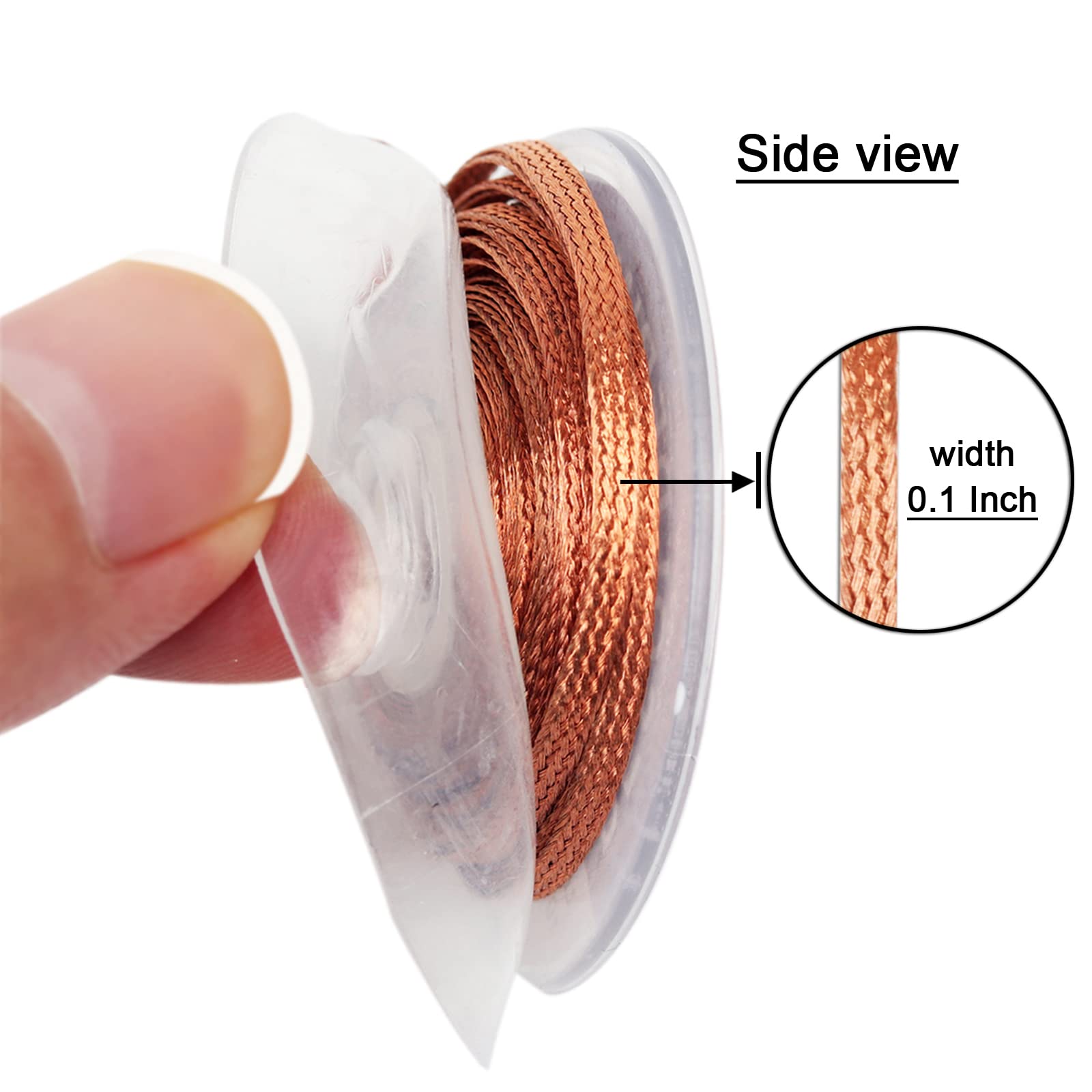

3.This desoldering wick has geometrically-precise weave with copper, work from the tip of the desoldering wick, once the desoldering wick and the solder has been heated, the solder braid can quickly absorbed molten solder and left a clean working area.

-

4.The desoldering wicks are made of copper wires with nice quality, precise weaving design can improve the capillary effect and the redundant solder absorbing ability, increasing your efficiency

-

5.The braided solder wicks are suitable for labs, home and industry welding work, practical tools to remove solder and correct errors on small PCB boards, bringing lots of convenience for your work

About Lesnow Solder Wicks Braid,Solder Sucker,10ft

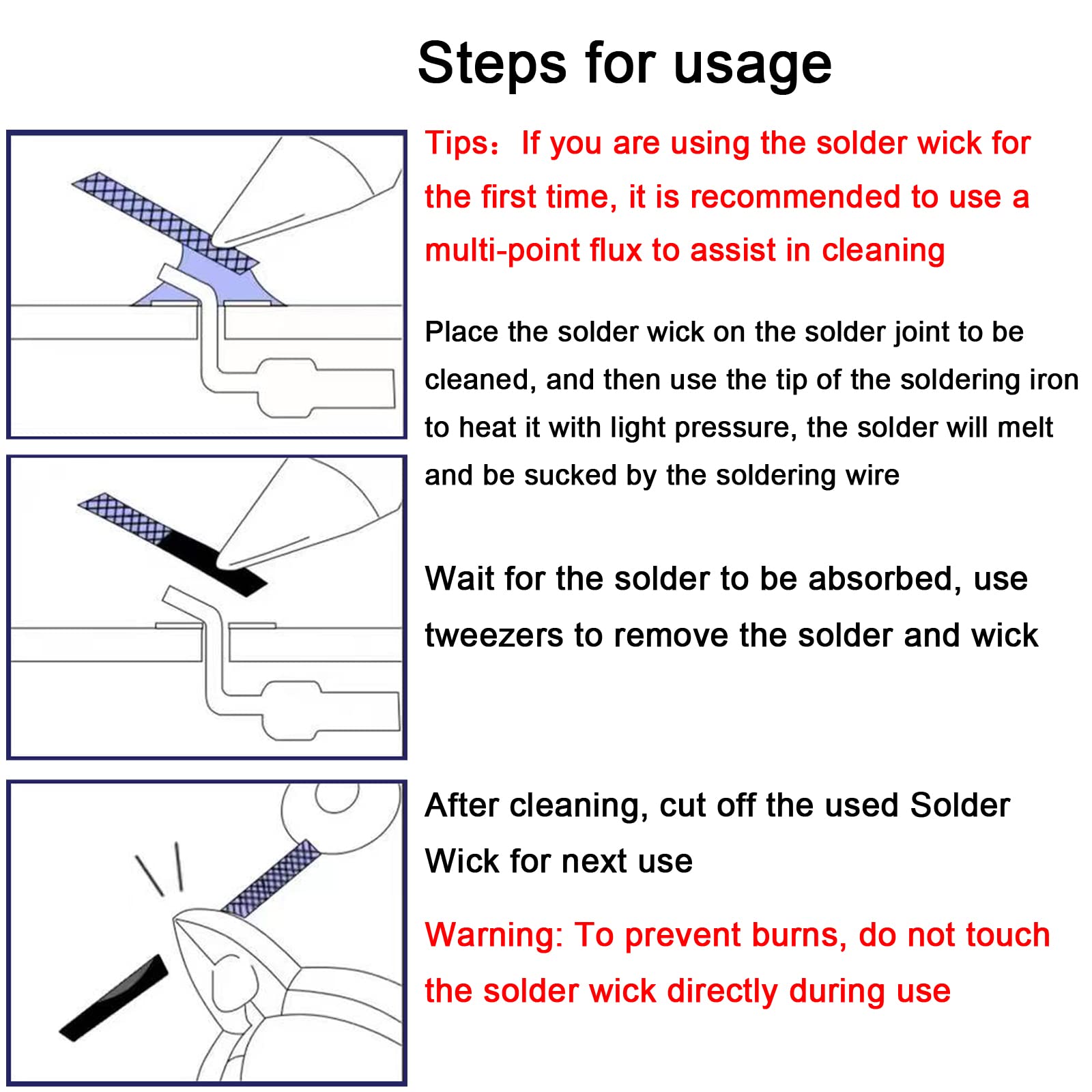

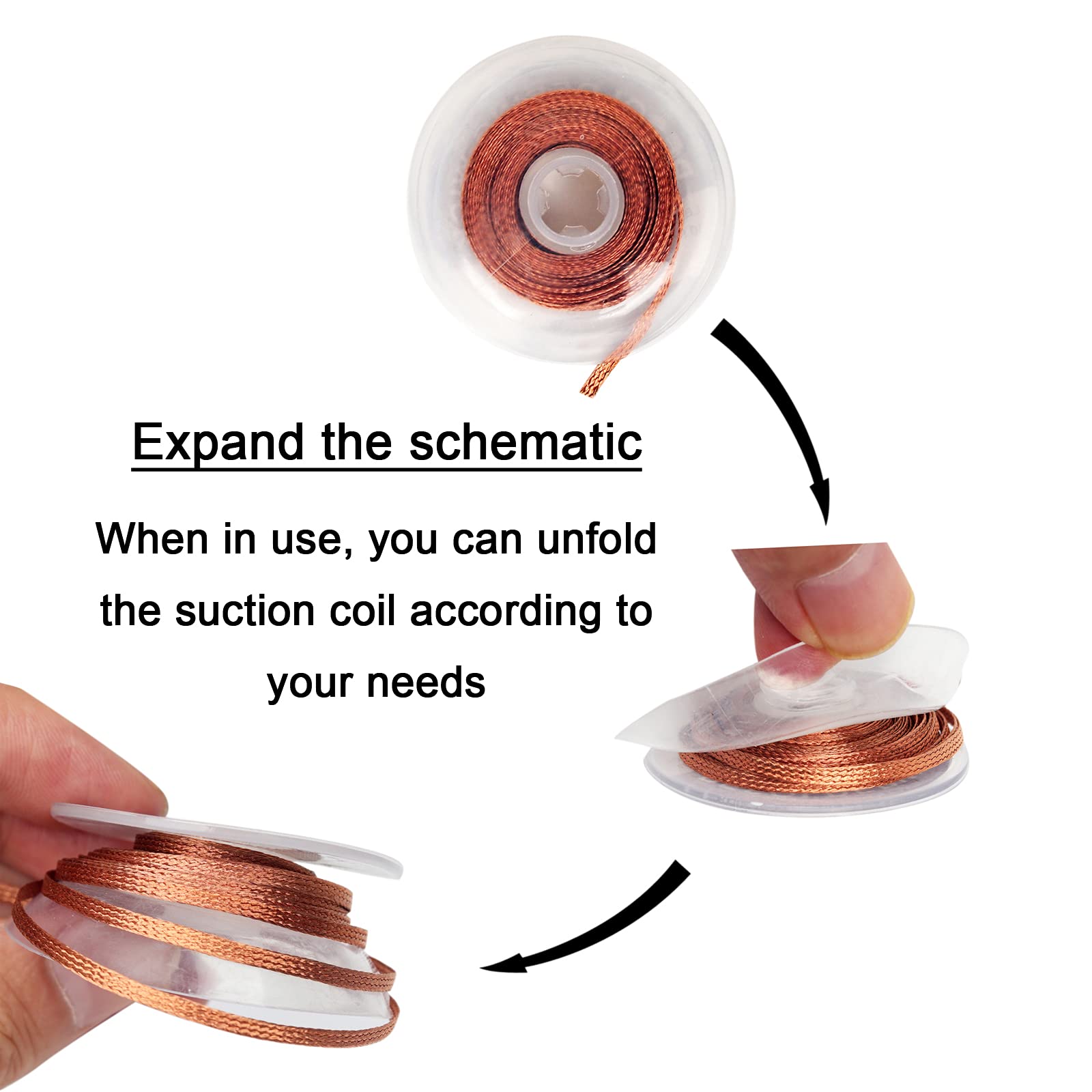

➤Specification: Width: 0.1 inch Length: 10feet ➤ Nice performance: The solder braided wicks can improve the capillary effect and the redundant solder absorbing ability, increasing your efficiency, they will just leave little residues after use and the residues are non-conductive and non-corrosive, you do not need to spending time removing them from the boards. You don’t need to spend time recleaning the board ➤Wide use: The desoldering wicks are suitable for labs, home and industry welding work, practical tools to remove solder and correct errors on small PCB boards, clean small components, suitable for re-soldering and desoldering, easy to use and not making damage to the board. ➤How to Use the Solder Wick Step 1: Place the wick over the solder you need remove and then just push the heated soldering iron tip onto the wick; Step 2: Remove the wick once the solder has been absorbed; Step 3: Cut off the used part of the wick; Step 4: Repeat this process if needed