All Categories

Fibre Glast Fiberglass Sleeving – Cloth-Mesh Tubing Bonds & Reinforces Hoses, Hockey Sticks, Oars, Golf Clubs, Studs, Mandrels & Cylinders – Epoxy & Resin Compatible, 10 Oz, 1 Yard, Made in USA

Share Tweet

Get it between 2025-05-26 to 2025-06-02. Additional 3 business days for provincial shipping.

*Price and Stocks may change without prior notice

*Packaging of actual item may differ from photo shown

- Electrical items MAY be 110 volts.

- 7 Day Return Policy

- All products are genuine and original

- Cash On Delivery/Cash Upon Pickup Available

Fibre Glast Fiberglass Sleeving – Cloth-Mesh Features

-

Fiberglass Biaxial Braided Sleeve – Fibre Glast glass fiber tubing conforms to 0.5 in-2.5in cylindrical models, parts or tools. The twill weave expands, contracts and delivers lightweight uniform strength. Must use with epoxy or resin. 10 oz, 36" long.

-

A Reinforcement Wrap – Fiberglass sleeve is a simple way to strengthen prosthetics, hockey sticks, oars, hoses, studs, tools, sporting equipment or any mandrel. Use this woven wrapping to improve performance, minimize weight and maximize strength.

-

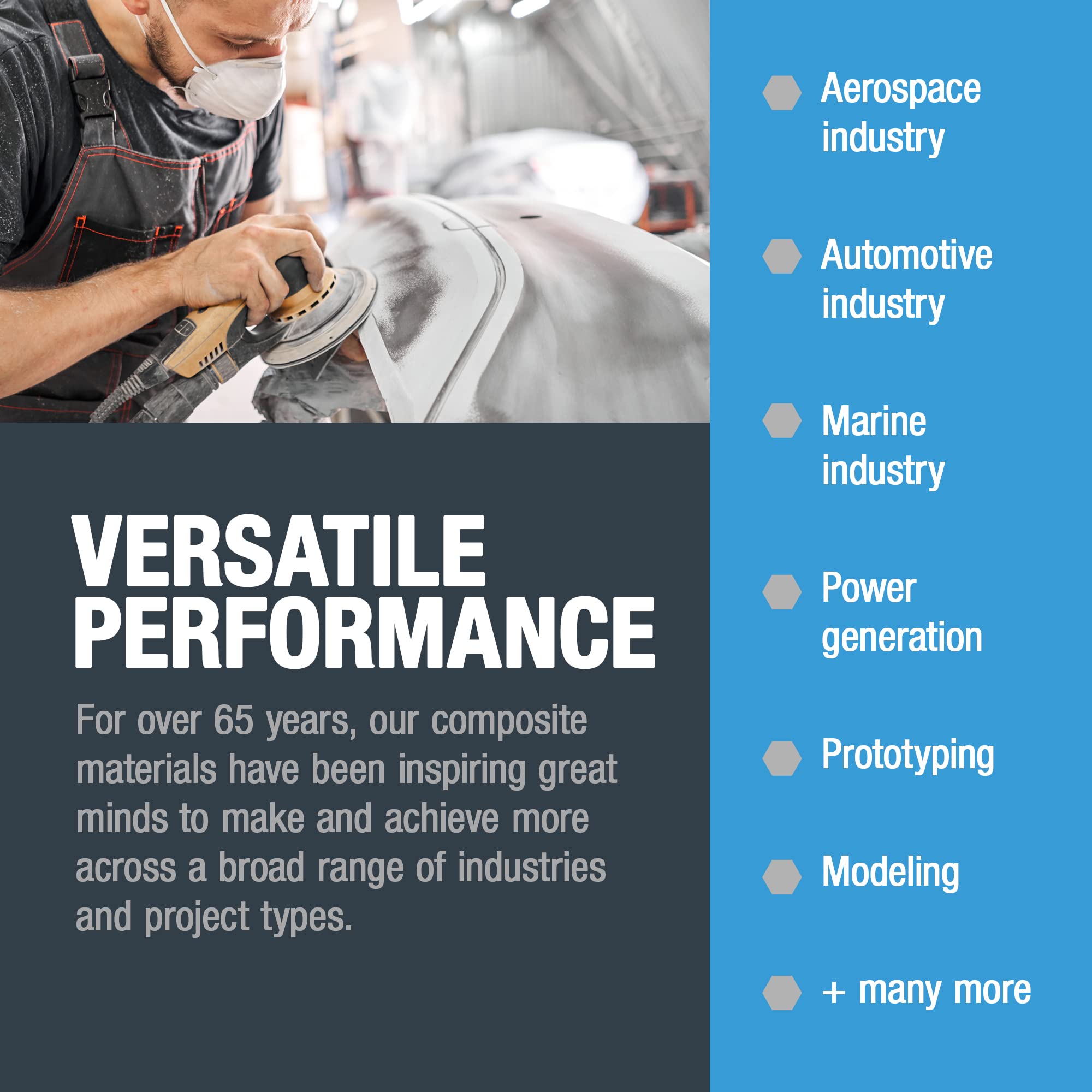

First Quality Certified – We only sell fabrics that are certified for the most demanding applications, from marine craft to space craft. "First Quality" means there will be no flaw or difference in product, from one order or batch to the next.

-

How To Use – Follow our guided instructions or use your own expertise to apply this reinforcement to a repair, build, tool or part. Transparent fiberglass tube is an easy alternative to winding your fabrications with roving, cloth mat or tape rolls.

-

The Fibre Glast Difference – We’re proud to be the trusted supplier of governments, contractors and big brands like the US Olympic Luge Team, and we look forward to earning your trust as well.

About Fibre Glast Fiberglass Sleeving – Cloth-Mesh

Braided sleeve will conform to the shape of products with changing geometries like prosthetics and hockey sticks, improving overall performance, minimizing weight, and maximizing strength. It can be slid over a prepared mandrel or cylinder to create straight or tapered tubing. The sleeve can be increased from a base diameter up to 30% and decreased by 70%. This means that our 2-inch sleeve can be used in a single application ranging from 0.6" to 2.6" in diameter. Braided sleeve is seamless, so it withstands internal pressure, distributes the load more evenly, and tolerates damage and fatigue. When the product is pressurized, it works much like a shark's body, orienting to the direction of force. If a puncture in the finished product does occur, the sleeve provides a slow, controlled failure, rather than a more damaging and potentially dangerous rupture. Laying up sleeve is predictable, repeatable, and suitable for precise manufacture of composite parts. It is extremely resistant to cracks between layers, reducing the possibility of delaminating and increasing the strength of the product.