All Categories

SUNLU Marble PLA Filament 1.75mm, Good Vacuum Packaging 3D Printer Filament, 3D Printing Filament 1.75mm Dimensional Accuracy +/- 0.02mm, 1kg Spool(2.2lbs), 330 Meters, White Rock Stone Marble Color

Share Tweet

Get it between 2025-03-12 to 2025-03-19. Additional 3 business days for provincial shipping.

*Price and Stocks may change without prior notice

*Packaging of actual item may differ from photo shown

- Electrical items MAY be 110 volts.

- 7 Day Return Policy

- All products are genuine and original

- Cash On Delivery/Cash Upon Pickup Available

SUNLU Marble PLA Filament 1.75mm, Good Vacuum Features

-

①【Marble Pattern Texture】SUNLU marble PLA 1.75mm filament has natural and realistic marble texture, which is very suitable for printing 3D buildings, ornaments and other special models.

-

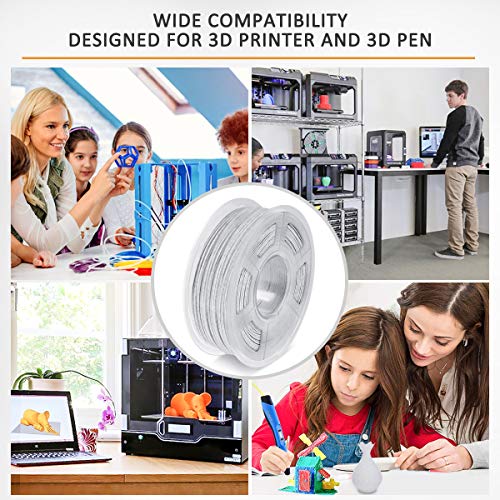

②【PLA 1.75mm Diameter】Dimensional Accuracy +/- 0.03mm. SUNLU filament has wide compatibility due to the small diameter error, it's suitable for almost all 1.75mm FDM 3D printers.

-

③【SUNLU Spool Diameter】Spool Diameter: 8.00", Spool Width: 2.50", Spool Hub Hole Diameter: 2.20". The size of the SUNLU filament spool is suitable for hanging on a lot of FDM 3D printers.

-

④【Recommend Settings】We recommend printing at a Nozzle temperature of 210°C - 230°C (410°F - 446°F) and Bed temperature of 60°C - 80°C (140°F - 176°F).

-

⑤【SUNLU Professional Team】SUNLU is a high-tech enterprise specializing in R&D, production and sales of 3D printing filament, 3D printer, 3D pen and 3D resin. SUNLU has a professional team.

About SUNLU Marble PLA Filament 1.75mm, Good Vacuum

Marble Color 3D Printing PLA Filament which gives your printing a wonderful experience! Premier Material: Marble PLA is made out of starch and some special raw material. It has all features of PLA, additionally combines the characteristics of marble. Color: Marble Color N.W: 1KG(2.2lbs) Diameter: 1.75mm(Dimensional Accuracy +/- 0.03mm) Print Temperature: 210-220 °C Hot bed Temperature: 0-70°C Bubble: no-bubble Speed: 50-90mm/s High Quality & High Compatibility Strict production standard to guarantee high accuracy. Eco-friendly with high performance, no bubble, no jamming, no drawing. The filaments are universally designed and compatible with 3D Printers using 1.75mm diameter filament, with a dimensional accuracy of +/- 0.02mm. Marble Color make your 3d printing model perfect, Gorgeous surface, nature and unique textures ects. Coupled with premium raw material, transcend industry standard accuracy and strict control, let you enjoy the fun of smooth printing with Marble Color filament. Tips: 1. Nozzle : ≥0.4mm 0.4 mm or larger nozzle and low print speed is recommended 2. Pls do not start the cooling fan at first 3 layers of model. Set the layer 0.1mm will be the best surface smooth and shiny. Set the outer layer in a slowly speed , 50-90mm/s 3. Clean or change the nozzle before printing is good way to reduce jam if it was used for many times. 4. It’s better try to release the filament to its original status after print, and place remitting filament back to original vacuum bag and stock them in a cool and dry place after print. Filament can absorb moisture from air and affect its quality and performance.