All Categories

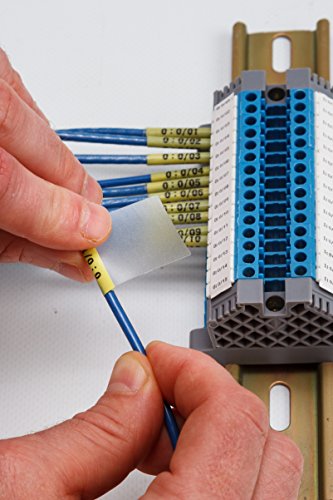

Brady Authentic PermaSleeve Heat Shrink Tubing (M21-187-C-342) and Self-Laminating Wire Wrap (M21-750-427) Labeling Materials

Share Tweet

of brand new stock?

or

Need this item ASAP?

Check if this is available on Amazon

or available in other sites

Send us the link so we can buy for you

Brady Authentic PermaSleeve Heat Shrink Tubing Features

-

Includes 3:1 heat-shrinking permasleeve wire labels resistant to chemicals, grease and oils for insulation and identification (M21-187-C-342).

-

Contains self laminating vinyl labels with acrylic adhesive for abrasion resistance and adhesion to irregular surfaces (M21-750-427).

-

Permasleeve labels provide smudge-proof black on white print quality that is compatible with BMP21-PLUS, BMP21-LAB, IDPAL and LABPAL label printers.

-

Self laminating labels provide translucent laminating layer over black on white print and are UL approved and CSA accepted.

About Brady Authentic PermaSleeve Heat Shrink Tubing

Brady Authentic (M21-187-C-342) PermaSleeve Heat Shrink Tubing for Control Panels, Electrical Panels and Wire Harness Labeling, Black on White material - Designed for BMP21-PLUS and BMP21-LAB Label Printers, .335" Width, 7' Length Brady leads the way in high performance identification solutions. At Brady, we have a steadfast commitment to providing our customers with innovative products and identification solutions. We use customer feedback to continually design, improve, and innovate our products to serve all of your needs, from general identification solutions to custom-engineered labels. Material developed in-house, by our experts. Highly focused on identification solutions, Brady's team of scientists and engineers work to provide you with products of the highest technological quality. At Brady's Tobey Research Center, material scientists rigorously test all label materials in-house to ensure high performance, industry compliance, durability, and reliability. More than 200 technologists in laboratory sites around the world More than 20 label material patents and growing Electro-mechanical, materials, and software development teams Materials designed to last and engineered to perform. The materials developed by Brady scientists are designed for a wide spectrum of applications and environments. Brady's in-depth knowledge of the conditions that products face requires extensive testing in harsh environments. Our products are not only designed to withstand the harshest of environments, but also designed with the user in mind. We spend time getting to know our customers in order to understand your needs. Brady Authentic (M21-750-427) Self-Laminating Wire Wrap for Control Panels, Electrical Panels and Datacom Cable Labeling, Black on White material - Designed for BMP21-PLUS and BMP21-LAB Label Printers, .75" Width, 14' Length Brady leads the way in high performance identification solutions. At Brady, we have a steadfast commitment to providing our customers with innovative products and identification solutions. We use customer feedback to continually design, improve, and innovate our products to serve all of your needs, from general identification solutions to custom-engineered labels. Material developed in-house, by our experts. Highly focused on identification solutions, Brady's team of scientists and engineers work to provide you with products of the highest technological quality. At Brady's Tobey Research Center, material scientists rigorously test all label materials in-house to ensure high performance, industry compliance, durability, and reliability. More than 200 technologists in laboratory sites around the world More than 20 label material patents and growing Electro-mechanical, materials, and software development teams Materials designed to last and engineered to perform. The materials developed by Brady scientists are designed for a wide spectrum of applications and environments. Brady's in-depth knowledge of the conditions that products face requires extensive testing in harsh environments. Our products are not only designed to withstand the harshest of environments, but also designed with the user in mind. We spend time getting to know our customers in order to understand your needs.