All Categories

Rapid Cure® Screen Printing Ink Fluorescent Purple (Gallon - 128oz.) - Plastisol Ink for Screen Printing, Screen Printing Paint for Fabric - Tshirt Ink by Screen Print Direct, Purple Ink

Share Tweet

Rapid Cure® Screen Printing Ink Fluorescent Purple Features

-

Easy to Use - Rapid Cure plastisol inks cure as low as 270°F compared to the average plastisol ink that cures at 320°F. Our screen printing paint is easier to use, with a much longer shelf life of over 12 months. Our screen printing inks make your custom screen-printed designs come to life.

-

Low Bleed and Very Versatile - Our silk screen ink allows you to print paint on a variety of textiles, such as cotton and polyester blends. Rapid Cure can also be used for plastisol heat transfers as well as cold peel transfers. Choose your favorite fabric screen printing method and go create.

-

Screen Print Ink with Style - Our fabric screen printing ink yields a bold, vibrant, and highly opaque color with a short body, making it easy to work with on your screen printing press and tshirts. Layer your inks with confidence, knowing you are using the best printing ink.

-

Tons of Options - From black screen printing ink to glitter ink, we have so many colors to choose from. With our Rapid Cure plastisol ink, you can cure quickly with a heat press, conveyor dryer, flash dryer, or heat gun. Great for DIY home screen printing.

-

Made in the USA - All of our silkscreen ink is made here in the USA and hand-scooped by SPD's very finest. Non-phthalate, non-toxic, and CPSIA-compliant.

About Rapid Cure® Screen Printing Ink Fluorescent Purple

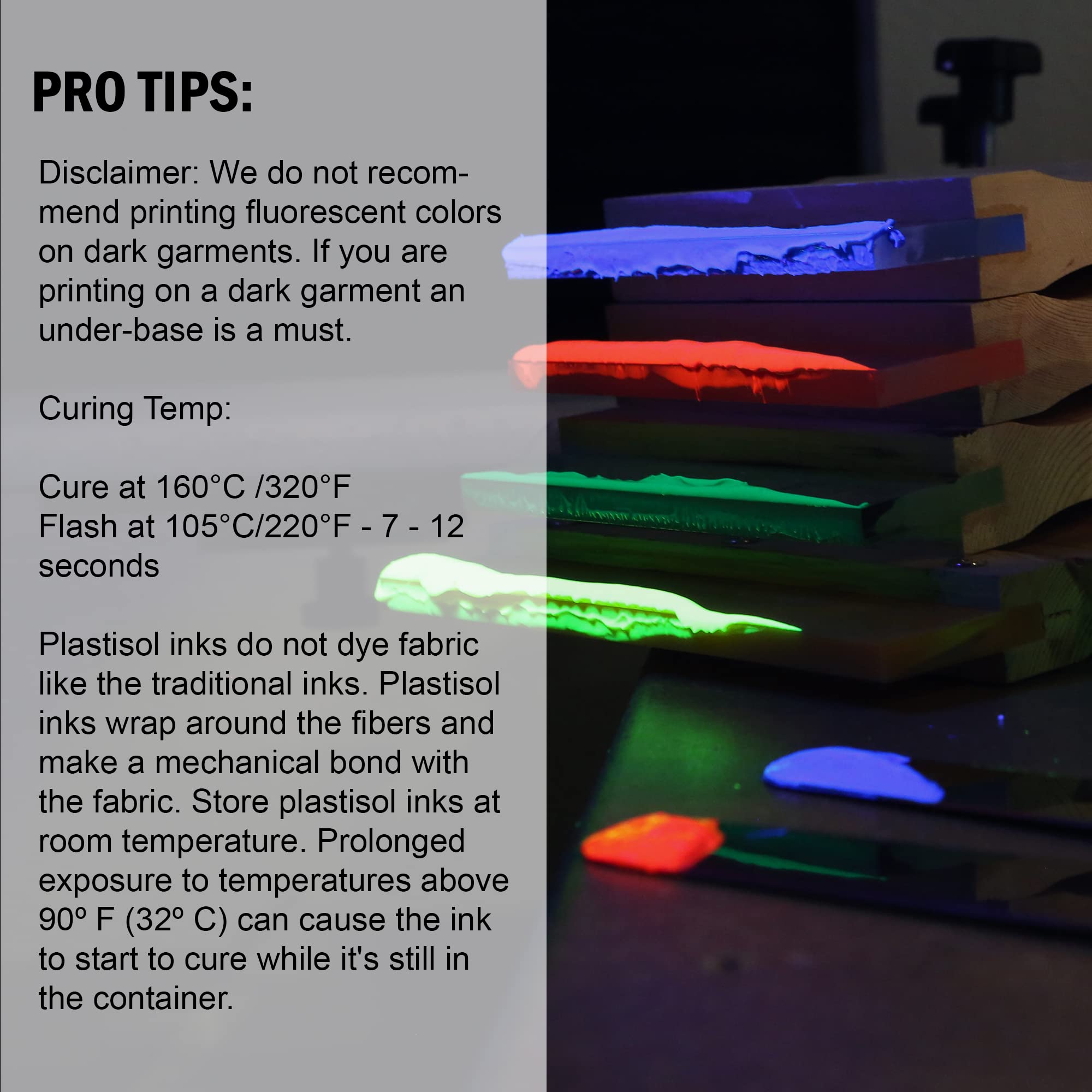

"Rapid Cure by Screen Print Direct is a premium plastisol ink that cures are low as 270°. Rapid Cure Plastisol Ink is the ideal ink when working with a variety of materials. This low bleed ink works great with a wide variety of blends including polyester. Say goodbye to garment shrinking and scorching with low temperature cure fabric ink. The inks lower cure temp saves production time and helps ensure the garment is cured properly without expensive conveyor dryers. The inks texture is creamy and short bodied. The color is vibrant, bold and opaque. For darker garments we recommend printing with an under-base. Disclaimer: All colors are approximate and will vary monitor to monitor. Curing: Cure at 132° C/270° F Flashing: Flash at 82-104° C/180-200°F Flash and Curing Guidelines: Generally, it will take 5-10 washes to fully test the cure, but if the ink is seriously under-cured, the print will show deterioration after only 1-3 washings washes. Another way to test your print quickly is doing the “Stretch Test” stretch the print roughly 2/3 of the T-Shirt; if the print cracks and does not retract back it means you under-cured. General Testing: Before you do any large print, we recommend doing a stretch test and a wash test to ensure you cured and printed correctly before going into production. Increase cure time if testing fails. We recommend only using natural fibers best results will be seen on 100% cotton. Clean Up: On the press: Ecotex Plastisol Press Wash/Ink Degradant In the sink: Ecotex Plastisol Screen Wash/Ink Degradant Pro Tips: Plastisol inks do not dye fabric like the traditional inks. Plastisol inks wraps around the fibers and makes a mechanical bond with the fabric. Store plastisol inks at room temperature. Prolonged exposure to temperatures above 90º F (32º C) can cause the ink to start to cure while it's still in the container."